Naphthalene Bioremediation With Petrox Microbes

Petrox Micorbes Remove Naphthalene and other SVOCs

Naphthalene is often a recalcitrant petroleum compound that keeps sites from clean closure. This resistance to remediation is due to naphthalene’s relative high adsorption and low solubility rates. Naphthalene has an aqueous solubility of 3.1E1 mg/l compared to benzene at 1.75E3 mg/l . Naphthalene has an affinity of adsorption expressed as the octanol/water partition coefficient (log Kow) of 3.26, while benzene has a log Kow of 2.13. For further comparison, acetone has a high water solubility at 1E6 mg/l and low log Koc of -0.24. In a study of relative degradation rates, the USEPA found a first order kinetic constant of 14.0 L/hg for naphthalene and 0.234 for benzene in activated sludge. Despite these challenges, naphthalene bioremediation with Petrox microbes has been successful at many spill sites.

Microbes initiate metabolism of naphthalene by inserting two oxygen atoms into the naphthalene structure. This initial step is catalyzed by naphthalene dioxygenase. Tests of sites inoculated with Petrox microbes show naphthalene dioxygenase at 1E8 to 1E10.

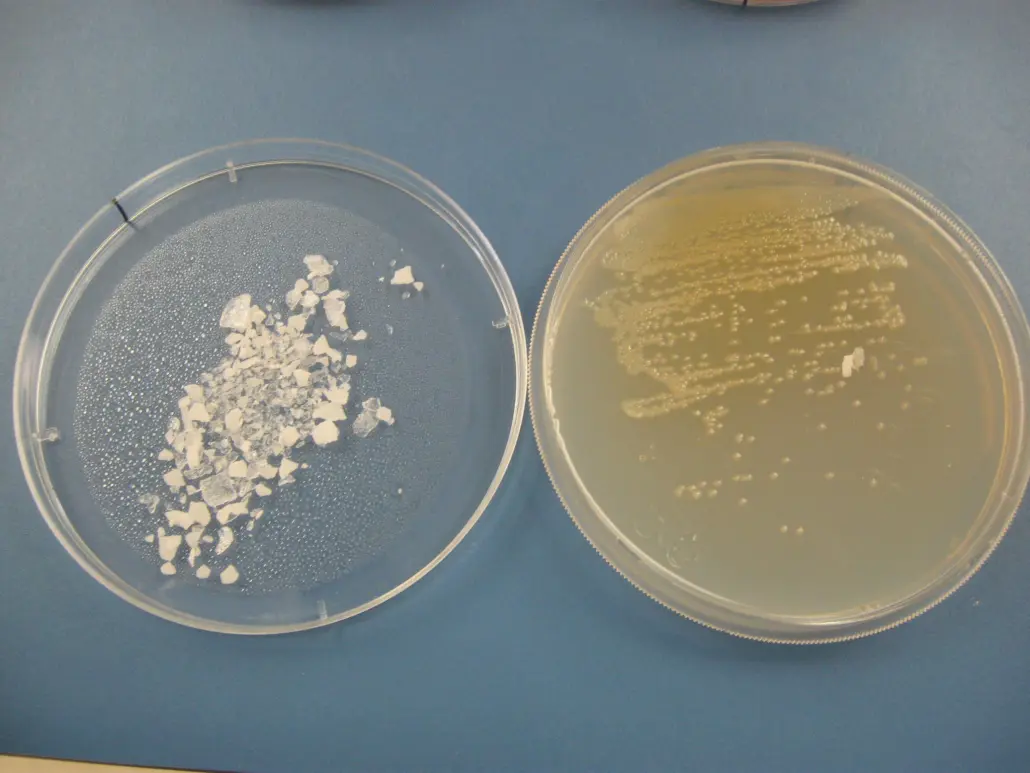

Petrox microbes thrive on naphthalene to the extent that naphthalene is occasionally used in the QA/QC process to verify Petrox viability and effectiveness. In this test, the Petrox organisms are placed on an agar devoid of a carbon source. The naphthalene is applied to the top plate as the sole carbon source. The Petrox viability is then demonstrated by colony growth on the top plate as shown on the following picture.

Click here and here to view cases studies of naphthalene bioremediation case studies.

Case Study:

Orange County Fire and Rescue Station 81, Orlando, Florida

Oculus Number 8520434

Petrox was used to treat the residual petroleum contamination in ground water after the leaking tank was removed. The petroleum contamination exceeded applicable standards for benzene, toluene, ethylbenzene, and xylene (BTEX) and naphthalene. Petrox was injected into the ground water through 28 injection points covering a plume area of approximately 6,300 square feet. Petrox injections were completed on June 18, September 11, and November 1, 2002.

Prior to bioaugmentation 100 pounds of ORC was added to provide supplemental oxygen for the bioremediation. After verifying the dissolved oxygen concentration was more than 1.0 mg/l, the site was ready for bioaugmentation.

During the first injection 10 drums of Petrox were injected to cover the full plume. As the area of contamination decreased, less Petrox was injected. Five drums were injected in a focused application on September 11 and November 1, 2002.

Quarterly monitoring was completed during and after the inoculation to determine the bioremediation results. The cleanup goals were achieved in the source area after the first inoculation. The contamination persisted, however, in the down gradient wells. The cleanup goals were achieved in the down gradient monitoring well after the third injection, but there was subsequent rebound. After full distribution of Petrox was reached throughout the plume, the BTEX and naphthalene bioremediation achieved cleanup goals.

Please refer to the table below for the ground water monitoring results.

| Monitoring Well | Date | Benzene | Toluene | Ethylbenzene | Total Xylenes | Naphthalene |

| MW-7 Source Area | 6/12/2000 | 5.0 | 46.0 | 18.0 | 90.0 | 24.0 |

| 6/13/2001 | 39.0 | 272.0 | 167.0 | 526.0 | 26.0 | |

| 3/14/2002 | 21.0 | 19.0 | 102.0 | 266.0 | 39.0 | |

| 6/5/2002 | ORC Added | |||||

| 6/18/02 | 10 Drums of Petrox Added | |||||

| 7/14/2002 | <1.0 | <1.0 | <1.0 | <2.0 | <1.0 | |

| 9/11/2002 | <1.0 | <1.0 | <1.0 | <2.0 | <1.0 | |

| 9/11/02 | 5 Drums of Petrox Added | |||||

| 10/7/2002 | <1.0 | <1.0 | <1.0 | <2.0 | <1.0 | |

| 11/1/02 | 5 Drums of Petrox Added | |||||

| 12/2/2002 | <1.0 | <1.0 | <1.0 | <2.0 | <1.0 | |

| 1/9/2003 | <1.0 | <1.0 | <1.0 | <3.0 | <5.0 | |

| 4/17/2003 | <1.0 | <1.0 | <1.0 | <2.0 | <1.0 | |

| MW-8

Down Gradient |

6/12/2000 | 2.0 | 72.0 | 21.0 | 109.0 | 39.0 |

| 6/13/2001 | 14.8 | 677.0 | 207.0 | 1292.0 | 113.0 | |

| 3/14/2002 | 71.0 | 1198.0 | 357.0 | 2408.0 | 193.0 | |

| 6/5/2002 | ORC Added | |||||

| 6/18/02 | 10 Drums of Petrox Added | |||||

| 7/15/2002 | 19.0 | 515.0 | 170.0 | 690.0 | 39.0 | |

| 9/11/2002 | <1.0 | 3.7 | 3.8 | 16.4 | <1.0 | |

| 9/11/02 | 5 Drums of Petrox Added | |||||

| 10/7/2002 | 6.4 | 2.3 | 4.7 | 23.8 | 15.0 | |

| 11/1/02 | 5 Drums of Petrox Added | |||||

| 12/2/2002 | 38.0 | 515.0 | 95.0 | 460.0 | 10.0 | |

| 1/9/2003 | <1.0 | <1.0 | <1.0 | <3.0 | <5.0 | |

| 4/17/2003 | <110.0 | 1060.0 | 285.0 | 1120.0 | 65.0 | |

| 4/29/2004 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | |

| 9/1/2004 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | |

| 12/1/2004 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | |

| 3/21/2004 | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | |

Contact CL Solutions for a free consultation to find out whether bioremediation is right for your site.

Case Study: Horizontal Injection for BTEX and Naphthalene Remediation

In situ remediation is a contact sport, requiring contact between the microbes and contamination. Clay-rich soils are particularly challenging as the low permeability limits effective distribution of inoculants. While numerous closely-spaced injection points can improve the distribution of inoculants, this approach is often not possible at active properties and can be costly. Horizontal drilling was used on the subject site to overcome the combined challenges of low permeability and limited site access to inject Petrox® microbes for bioaugmentation. The combined technologies reduced the total BTEX concentrations in ground water from 2,771 µg/L to 645 µg/L in less than one year.

Background

The site is a former gas station located in the Florida panhandle. The site soils are mixed silt and clayey silts that are typical of the coastal setting. The depth to the water table varied seasonally from 13 to 18 below ground surface.

The underground storage tanks and contaminated soil had been removed prior to the ground water treatment. Residual ground water contamination exceeded Florida Ground Water Cleanup Target Levels (GCTLs) for benzene, toluene, ethylbenzene, xylene, naphthalene and methylnaphthalene isomers.

The proposed treatment area was approximately 2,500 square feet. The treatment depth was from 10 to 25 feet below grade. The treatment depth included the capillary fringe to treat residual contamination above the seasonal low water table.

Horizontal Injection

Access to the treatment area was limited by the current property use, the proximity of roads on two sides and a building on the third. Horizontal drilling was selected by the site consultant, Advanced Environmental Technologies (www.aetllc.com) to deliver Petrox® to the contamination.

The horizontal drill rig was set back from the treatment zone on the opposite side of the building. The horizontal injection wells were set in four horizontal sets of eight wells. The horizontal layers were at 10, 15, 20 and 25 feet deep. The wells in each layer were five feet apart. A total of 32 injection wells were closely spaces for excellent coverage through the treatment zone.

Petrox® was injected into the ground water in two treatment events – November 6, 2008 and June 24, 2009. Petrox® was delivered in each injection well as the drill stem was withdrawn through the treatment zone. The injection was monitored for accuracy so that 0.2 gallons of Petrox® was injected per foot of injection zone. A total of 320 gallons of Petrox® slurry was injected.

Following the Petrox® injection, air was injected periodically through vertical sparging wells to increase the oxygen availability for the microbial metabolism.

Results

Ground water samples were collected from a monitoring well inside the treatment area to track the progress of the bioremediation. Approximately 60 days after the first Petrox® treatment, analysis of ground water samples showed 84% reduction in the benzene concentration and 35% reduction in the total BTEX compounds concentrations. There was an apparent increase in the xylene concentration due to ground water mixing and induced increase in solubility due to the bioaugmentation injections.

A second sampling event approximately 30 days after the second injection showed additional reduction in the contaminant concentrations. After the second injection, the total BTEX concentrations were 23% of the original concentration with xylene decreasing from 1,200 to 95 µg/L.

In addition to the BTEX compounds, naphthalene and methylnaphthalene isomer concentrations decreased through both treatments.

| Sampling Date | Benzene | Toluene | Ethylbenzene | Xylene | Naphthalene | |

| Pre-treatment | 11/11/05 | 3,000 | 42 | 1,100 | 1,100 | 230 |

| 10/23/08 | 1,700 | 18 | 460 | 454 | 280 | |

| 11/6/08 | 1,600 | 41 | 370 | 760 | 310 | |

| Post-treatment

|

1/22/09 | 420 | 43 | 140 | 1,200 | 43 |

| 7/30/09 | 490 | 2.6 | 57 | 95 | 55 |

Conclusions

Horizontal drilling and injection made it possible to remediate ground water at this site of petroleum contamination with limited access and low natural permeability. Without disturbing the property use, the horizontal injection of Petrox® provided effective distribution of the microbes for bioremediation. The injection may have also made the contamination more available for bioremediation by increasing the contaminant solubility as shown by temporary increases in concentration.

This case study demonstrates that in situ bioaugmentation may be a feasible solution for sites with limited permeability and access restrictions. For more information contact CL Solutions at www.cl-solutions.com.

Case Study: South Carolina Industrial Site

Petrox microbes were injected in a petroleum ground water plume for naphthalene bioremediation to remove contamination at an industrial site. With one application, the petroleum constituents were below detection limits in under six months.

| Sampling Date | Benzene

(ug/L) |

Toluene

(ug/L) |

Ethylbenzene

(ug/L) |

Xylene

(ug/L) |

Naphthalene

(ug/L) |

|

| Pre-Injection | 1/8/14 | 210 | 1,100 | 180 | 3,500 | 530 |

| 30 Days After | 4/25/14 | 58 | 300 | 28 | 1,100 | 65 |

| 6 Months After | 9/3/14 | <0.2 | <1.7 | <1.7 | <1.7 | <1.7 |

Petrox is a blend of Pseudomonas sp. formulated to degrade a wide range of petroleum hydrocarbons including BTEX and naphthalene bioremediation. The application of Petrox at the case study site overcame some of the recalcitrance of xylenes and naphthalene that can result in slow remediation.

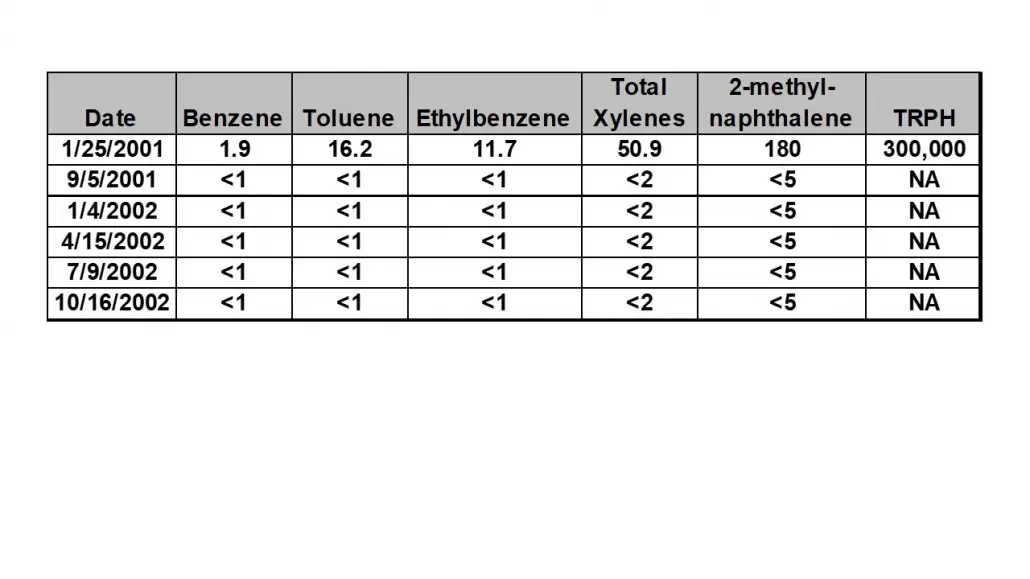

Case Study: Petrox and Methylnaphthalene Isomers Bioremediation

Petrox microbes accelerated BTEX and methylnaphthalene bioremediation at a former fueling station in Florida. After a leaking tank underground storage tank (UST) was removed, the consultants injected Petrox micorbes into the groundwater. A temporary well showed high concentrations of BTEX, methylnaphthalene isomers, and total recoverable petroleum hydrocarbons (TRPH) in the former tank location. A permanent monitoring point replaced the temporary well. Since the contaminants were not detected outside of the UST cavity, the treatment focused on the cavity and its proximity. The consultant injected Petrox into the ground water through 12 direct-push injection points in and around the UST cavity. They used approximately 10 gallons of Petrox solution at each of the injection points in August 2001. After one injection of Petrox, petroleum hydrocarbons concentrations decreased below detection levels in the UST cavity. Please refer to the table below for the ground water monitoring results.

Persistence in Soil and Low Ground Water Concentrations

Methylnaphthalene and naphthalene persist in soil after other volatile components of fuels are gone. The persistence comes from to their relatively high affinity for adsorption to soil and relatively low water solubility. These factors account for the common rebound of ground water concentrations. Despite high concentrations of naphthalene and methylnaphthalene in soil near the ground water table, often the dissolved concentration in the ground water is very low. The accumulation of these compounds at the water table causes a problem for remediation. Frequently after ground water remediation, seasonal fluctuation of the water table through the contaminated vadose zone recharges the concentrations of these compounds. This results in seasonal fluctuation in the ground water concentrations.

Methylnaphthalene Metabolism

The microbes in Petrox accelerate the remediation because they product an extracellular biosurfactant that desorbs the methylnaphthalene to make it available for extraction or for in situ bioremediation. At this site, the contaminated soil was removed to the water table, so concentrations did not rebound after the initial ground water remediation. At other sites where Petrox bioremediation addressed methylnaphthalene or naphthalene, the consultant combined bioremediation with extraction. The combined technologies removed the contamination flushed from the soil in addition to the bioremediation. Click here to view case studies from other sites.