Fast, Reliable Industrial Bioremediation

CL-Out microbes remove PCE, TCE and other industrial solvents from soil or water by aerobic cometabolic bioremediation. This method has been used to restore the environmental conditions and property value at many industrial locations, where degreasing or other solvents have been spilled. Solvent remediation with CL-Out microbes saves time and money by working with the natural site conditions and using a high population of known beneficial microbes. Site closure often occurs in a matter of weeks or months versus several years or more for other methods, giving users the combined benefit of fast site closure and remarkable cost savings.

CL-Out aerobic bioremediation of PCE, TCE, 1,1,1-TCA and other industrial solvents is a sustainable process for soil and ground water remediation. As these compounds are not directly metabolized under aerobic conditions, the competitive advantage goes to the CL-Out organisms that cometabolize them. While utilizing a sugar substrate, the CL-Out organisms produce mono- and dioxygenase enzymes that bridge the carbon bond to destabilize the compound. The solvent is converted to an organic acid that the organism can metabolize. View the degradation pathway. The benefit is that CL-Out bioremediation can be applied to soils and water both in situ and ex situ.

How It Works

CL-Out cometabolism uses a dioxygenase enzyme that is produced constituatively as the metabolic substrate is consumed. The dioxygenase enzyme destabilizes the carbon bond in the PCE or TCE to convert the molecule to an organic acid that leads to complete mineralization. Click here to view the PCE and TCE cometabolic degradation pathways.

CL-Out is a consortium of naturally-occurring microbes. The microbes have the benefits of metabolic diversity and environmental stability. They are non-pathogenic and safe for human health and the environment. Click here to find out more about CL-Out bioremediation.

Case Study: Industrial Manufacturing Site, Illinois

Remediation Summary

Leaks from an aboveground solvent tank impacted soil and ground water quality at a manufacturing site in Illinois. The impact was found under the adjoining building as well as the area near the tank. The soil and ground water were treated in situ with CL-Out® bioremediation microbes. Through cometabolism CL-Out® microbes reduced the contaminant concentrations to acceptable levels in less than one year.

| Contaminants | Soil Results (mg/Kg) | Ground Water Results (mg/L) | ||

| Pre-Treatment | Post- Treatment | Pre-Treatment | Post- Treatment | |

| PCE | 41.8 | 1.69 | 5.59 | 0.006 |

| TCE | 4,670 | 632 | 15.6 | 0.026 |

| Cis 1,2-DCE | 171 | 56.6 | 7.43 | 0.029 |

| Vinyl Chloride | BDL | BDL | 0.095 | 0.013 |

Implementation and Results

Soil Type: Silty clay till

Treatment Area: 15,000 sq. ft.

Unsaturated soil thickness: 16 ft.

Saturated aquifer thickness: 5 ft.

Treatment: Two applications, initial treatment with 13 units of CL-Out® and follow up treatment with 5 units.

Product Cost: $30,000

Conclusions

CL-Out® bioremediation quickly and cost-effectively reduced the contaminant concentrations to acceptable levels. Through cometabolism the parent and daughter products were removed simultaneously. CL-Out® bioaugmentation accelerated the site remediation and reduced uncertainty by applying the right microbes where they were needed.

Case Study: Aerobic Cometabolism of PCE at an Industrial Site in Tampa, Florida

Project Summary

Degreasing solvents were found in the ground water at an industrial manufacturing facility in Tampa, Florida. The solvents include PCE and its associated breakdown products. The source of the ground water contaminants was found to be a former water treatment system drain field. CL-Out® bioremediation was implemented to reduce the volume of contamination in the source area and down gradient. CL-Out® is a consortium of Pseudomonas sp. that produces constitutive enzymes to cometabolize PCE and other halogenated solvents. Dextrose is added with CL-Out® to provide a substrate for microbial growth. Application of CL-Out® bioremediation at this site reduced the total chlorinated solvent concentrations as much as 99% in less than 6 months.

Geology and Hydrogeology

The site is located in Tampa, Florida where the geology is characteristically interbedded silt and sand. The background ground water redox conditions of the aquifer are not known.

Contamination

The PCE and elevated concentrations of daughter products were found in ground water down gradient of the former drain field. The PCE concentrations were as high as 280 µg/L and DCE concentrations were as high as 4,400 µg/L, which indicates that there was significant contaminant degradation occurring, but the natural degradation stalled at DCE. Petroleum hydrocarbons were also present in the ground water and may have served as an oxygen sink during the degradation of the petroleum products.

Remediation Design

CL-Out bioremediation was implemented in the ground water to accelerate the remediation of the source area. A 55-gallon slurry of CL-Out was injected on February 11, 2003.

Monitoring wells in the source area and surrounding area were sampled to assess the progress of the remediation. The following table shows the pre-treatment and post-treatment CVOC concentrations in a source area monitoring well (MW-1) near the application of CL-Out.

Source Area (MW-1)

| Sampling Date | CVOC Concentrations (µg/L) | |||

| PCE | TCE | DCE | VC | |

| 3/28/02 | 280 | 750 | 4,400 | BDL |

| 12/19/02 | 86 | 120 | 1,100 | BDL |

| 2/11/03 | CL-Out Injection | |||

| 2/24/03 | 350 | 280 | 1,600 | BDL |

| 7/7/03 | 4.6 | 6.0 | 63 | BDL |

RESULTS

After application CL-Out bioaugmentation the chlorinated solvent concentrations in MW-1 decreased by as much as 99%. Overall the total mass of contamination was significantly diminished by the bioaugmentation in a short period of time to accelerate the natural degradation.

Case Study: Vinyl Chloride Bioremediation in Central Ohio

Site Summary:

CL-Out® bioremediation removed vinyl chloride and other chlorinated solvents found in ground water at a former automobile repair shop. The solvents were thought to have been released from an underground storage tank (UST). After the UST and associated contaminated soil were removed, CL-Out bioremediation was implemented to reduce the levels of contamination to site-specific cleanup goals.

Geology

The site is set in the area of central Ohio where the ground moraine is relatively thin. The underlying bedrock is limestone with a very porous and heavily fractures surface. While the till of the ground moraine is relatively impermeable the bottom of the UST cavity was very close to the bedrock surface.

Hydrogeology

The affected ground water was in the weathered surface of the bedrock, which is a relatively prolific formation. The depth to the top of water was approximately 9 feet and the monitoring wells were screened to a total depth of 15 feet.

Contamination

The size of ground water plume that resulted from leaching soil contaminants was estimated to be 4,000 square feet. The original contaminant was suspected to be PCE, but the main contaminants at the time of the remediation were cis 1,2 DCE and vinyl chloride. There may have been naturally occurring organisms that degraded the PCE to DCE and vinyl chloride. CL-Out bioaugmentation was implemented to accelerate the natural process to achieve timely site closure.

Remediation Design

CL-Out bioremediation was implemented through temporary injection wells in the source area. Two applications of CL-Out were made between February and August 2008. Monitoring wells were sampled in the treatment area to assess the progress of the remediation. The following table shows the contaminant concentration treads in the monitoring well with the highest pre-treatment contaminant concentrations.

| Contaminant Concentrations (µg/L) | ||||

| PCE | TCE | DCE | Vinyl Chloride | |

| Pre-Treatment 11/13/07 | BDL | BDL | 10.0 | 80.0 |

| First Injection 2/29/08 – 1 Drum of CL-Out | ||||

| Post-Treatment 6/16/08 | BDL | BDL | 7.7 | 27.0 |

| Second Injection 8/12/08 – 2 Drums of CL-Out | ||||

| Post-Treatment 9/4/08 | BDL | BDL | 1.6 | 4.6 |

| Post-Treatment 12/9/08 | BDL | BDL | 1.3 | BDL |

Maintaining Aerobic Conditions

CL-Out bioremediation is aerobic cometabolism that uses dextrose as the growth substrate. Oxygen is required for the metabolism of the dextrose and to supply oxygen for the oxygenase enzyme that is responsible for the destruction of the DCE and vinyl chloride molecules. During the project dissolved oxygen levels (DO) and redox conditions (ORP) were monitored. Prior to CL-Out remediation the DO average was 1.4 mg/L and the ORP was -62. With clearly anoxic site conditions, CL-Out bioremediation was selected, but the redox conditions were monitored to be sure the conditions did not fall out of the effective range for CL-Out bioremediation.

As the remediation progressed, the DO and ORP decreased to 0.42 and -225 respectively. During the August 12, 2008 CL-Out application, ORP socks were installed in two monitoring wells to maintain aerobic conditions for the remainder of the project.

Microbial Population

CL-Out consists of naturally-occurring Pseudomonas sp. organisms. The background population of Pseudomonas sp. was tested prior to CL-Out bioaugmentation. The background population was 19,000 cfu/ml. The target population for effective remediation is 1,000,000 cfu/ml. Thirty days after CL-Out bioaugmentation the population of Pseudomonas sp. was 840,000 cfu/ml in a down gradient monitoring well.

Results

After two small treatments, the contaminant concentrations in the source area were reduced to acceptable levels. There was no rebound in the four months of post treatment monitoring.

Case Study: CL-Out Completes Remediation After Stalled Natural Attenuation

Investigation of an industrial dry cleaners near Philadelphia, Pennsylvania found concentrations of breakdown products of PCE in the soil and ground water. The parent PCE presumably was reductively dechlorinated to TCE, DCE and vinyl chloride. However, since the daughter products DCE and vinyl chloride are more readily degraded under aerobic conditions, the breakdown was incomplete and natural attenuation stalled. CL-Out bioremediation was applied with an oxygen supplement to complete the remediation under aerobic conditions favorable for DCE and vinyl chloride bioremediation.

Geology

The geology of the property is interbedded sandy silt, silt and clay layers. The contamination was found in a shallow silty sand formation that is underlain by a dense clay layer. A sand layer directly beneath the clay layer was unaffected by the contamination in the upper sand.

Hydrogeology

The perched ground water was within a fill layer, so the hydraulic conductivity was expected to be variable. Slug testing results showed the hydraulic conductivity in the upper sand ranged from 1.1 to 3.9 ft/day. The ground water flow direction was consistently toward a local surface stream. The extent of the contamination plume was approximately 10,000 square feet.

Ground Water Contamination

The contaminants found at the site were mainly TCE and DCE with trace levels of vinyl chloride. This suite of contaminants indicated that there was natural degradation of the PCE to lesser halogenated compounds. The maximum concentrations prior to bioaugmentation were 220 ug/L of DCE, 9.2 ug/L of TCE and 31 ug/L of vinyl chloride.

Remediation

CL-Out was introduced into the ground water through one-inch diameter tubing installed using a direct push sampler. The use of small diameter injection points made the remediation possible without disruption the dry cleaner operations. Three injection points were installed in the high concentration area. Additional injection was made in places where shallow soil had been excavated.

The CL-Out injection was a dosing of four drums in December 2005.

Results

Three months after the injection of CL-Out, the DCE concentration dropped from 200 to 54 ug/L. The vinyl chloride concentration decreased from 31 to 11 ug/L. After seven months the TCE and vinyl chloride concentrations were below detection limits and the DCE concentration decreased to 2.9 ug/L.

Due to the relatively anoxic conditions, an oxygen supplement was added to support the aerobic cometabolism. During the active treatment the dissolved oxygen levels increased from 1.9 to 8.5 mg/L. The CL-Out microbial population was maintained at 200,000 cells per milliliter.

The monitoring results suggest that by supplementing the dissolved oxygen levels, the CL-Out population was maintained for an extended period. The extended peak of CL-Out population made possible a greater level of contaminant removal.

Case Study: Combined CL-Out Bioremediation and Dual Phase Extraction

Site Summary

CL-Out® bioaugmentation was implemented in combination with dual phase extraction at an industrial site near Houston, Texas to remove trichloroethylene (TCE) from ground water. The overlying contaminated soil was excavated, but perched ground water and a deeper aquifer had TCE concentrations greater than 10,000 µg/L. A dual-phase vacuum extraction system was installed to control the ground water gradient and increase distribution of the CL-Out® organisms in the aquifer. The TCE concentrations were reduced by 99.9% in one year.

Geology and Hydrogeology

The site is located on coastal plain sediments characteristically interbedded sands, silts and clays. The first impacted ground water was a thin perched layer 16 to 18 feet below ground surface. A more transmissive, water bearing zone was at 25 to 30 feet deep. Both water-bearing layers and the interbedded fine-grained layers had TCE concentrations above regulatory standards.

Contamination

High concentrations of TCE were present in perched and deeper ground water. Prior to treatment, a small area of soil less than 500 square feet had TCE concentrations greater than 20,000 µg/L. The underlying impacted perched ground water area was the same size and had TCE concentrations up to 30,000 µg/L. The TCE migrated laterally in the underlying deeper ground water where the TCE concentrations were greater than 10,000 µg/L. The area of the deeper ground water plume was approximately 30,000 square feet.

Remediation

The contaminated unsaturated soil was excavated for treatment to the perched ground water. The perched ground water was treated by a combination of potassium permanganate and vapor extraction. The deeper aquifer was treated by a combination of dual-phase extraction and CL-Out® bioremediation.

CL-Out® was applied eight times between January, 2010 and February, 2011. During each application 55 to 110 gallons of CL-Out® was injected into the ground water. The dual-phase extraction system was used to control the ground water gradient and induce greater distribution of the CL-Out® microbes. Periodic plate count analysis of the microbial population in the treated aquifer was completed to guide where and when the CL-Out® population should be supplemented. The repeat applications were on approximately 4 to 6 week intervals.

Results

Following one year of bioaugmentation, the contaminant concentrations were reduced by more than 99%. The daughter products caused by incomplete natural breakdown were removed as well as the TCE. The following table shows the contaminant concentration trends in the treatment area.

Case Study: Cometabolism of 1,1,1-TCA in a Mixed Solvent Plume

One of the benefits of CL-Out cometabolism is that the enzymes produced by the Pseudomonas sp. organisms convert a wide range of organic chemicals into organic acids that can be metabolized. The aggressive application of CL-Out organisms to soil and ground water at a chemical mixing company removed the source of ground water contamination by chloroethanes and chloroethenes, including PCE and 1,1,1-TCA. The aerobic cometabolism of these compounds achieved MCLs in less than 6 months. Click here to view the case study Mixed Solvent Plume Cometabolism by CL-Out

Case Study: TCE and 1,1,1-TCA Bioremediation at Indiana Industrial Site

TCE and 1,1,1-TCA bioremediation by CL-Out organisms reduced contaminant concentrations in ground water under a drum storage area at a central Indiana industrial site. After three monthly applications of CL-Out microbes, the in situ treatment reduced total maximum CVOC concentrations from 102 mg/L to 3 mg/L in less than 6 months. Click here to view the complete case study.

Case Study: CL-Out Bioaugmentation Following ISCO to Remediate TCE

CL-Out bioremediation was used to remediate ground water at an active manufacturing plant in eastern Massachusetts after ISCO treatment of TCE in groundwater reached a limit. CL-Out was selected because the aquifer was naturally aerobic. CL-Out cometabolizes TCE and other chlorinated solvents under aerobic conditions by producing an oxygenase enzyme that breaks the carbon to carbon bond. Under aerobic conditions daughter products such as DCE and vinyl chloride are not formed. 30 days after one application of CL-Out the TCE concentration was reduced by 97% and the site remediation goals were achieved. Click here to download the case study.

Case Study: CL-Out Bioremediation of Solvents at a Chrome Plating Facility

CL-Out® aerobic cometabolism successfully remediated solvents in ground water at an operating industrial site in central New Jersey. The manufacturing and plating facility had historical petroleum and solvent releases.

Chlorinated solvents found in the ground water in two plumes covered a combined area of about one half acre. A mix of chlorinated solvents including 1,1,1-TCA, 1,1-DCE and PCE in low concentrations icontaminated the ground water. The remediation goal was to reduce the mass of contamination in the ground water plume to prevent mitigate off-site risks.

After the CL-Out aerobic cometabolism, ground water concentrations in all monitoring wells decreased by more than 80%, which was sufficient to meet the remediation standards. Click here to download a complete case study.

Case Study: Bioremediation of 1,1,1-Trichloroethane and 1,1-Dichloroethene

Background

CL-Out® bioaugmentation was used to remediate ground water contaminated by 1,1,1-trichloroethane (1,1,1-TCA) and 1,1-dichloroethene (1,1-DCE). The 1,1-DCE was formed as a product of the natural abiotic degradation of 1,1,1-TCA. The bioremediation was implemented as a pilot study and a subsequent interim action for source removal.

Remediation Approach and Results

CL-Out® was introduced into the contaminated ground water in the suspected source area by injection through temporary well points up gradient of the monitoring point. The initial application was in March 2007 and a subsequent application was completed in September 2007.

The ground water treatment results were monitored by analysis of ground water samples for the contaminants of concern. The 30-day monitoring results after the first application showed an immediate decrease in the contaminant concentrations. After 30 days, the 1,1,1-TCA concentration decreased from 1,000 µg/L to 190 µg/L and the 1,1-DCE concentration decreased from 160 µg/L to 27 µg/L . Long-term monitoring after the second application showed that the concentrations of both compounds were reduced to 1.4 µg/L. The following chart shows the long-term contaminant concentrations.

Conclusions

This project demonstrates several of the benefits of aerobic bioaugmentation. CL-Out® organisms were able to metabolize the parent chloroethane compound and the daughter product, which was a chloroethene compound. The metabolic diversity of the CL-Out® organisms facilitates enables the bioremediation of mingled plumes and multiple contaminants. Bioaugmentation provides active control of the site as effective organisms compatible with the site conditions were injected where they were needed for quick contaminant removal.

Case Study: TCE Bioremediation in Kentucky

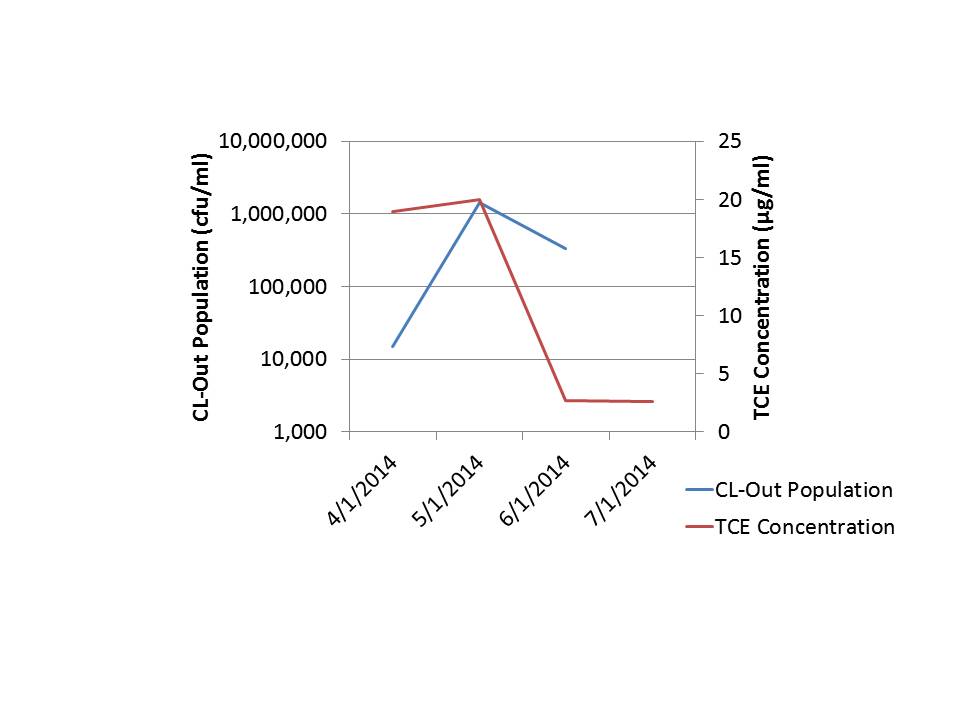

CL-Out bioaugmentation was used to reduce the TCE concentrations in ground water at an industrial site in Louisville, Kentucky. CL-Out microbes were injected into the TCE-contaminated ground water. Dextrose was added to provide the carbon source for the microbial growth. An oxygen supplement was necessary to maintain aerobic conditions in the aquifer.

Ground water sampling downgradient of the injection points showed that the CL-Out microbial population achieved a target population of 1 million cfu/ml and maintained an effective population for at least 60 days. During that timeframe the TCE concentrations were reduced by 90%.

Case Study: CL-Out Bioremediation of Brownfield Contamination

A brownfield plan included Cl-Out bioremediation to reduce high concentrations of TCE and other contaminants in ground water at an industrial site near Newark, New Jersey. Using a dynamic remediation plan, three applications of CL-Out microbes followed remediation progress sampling during the site preparation for construction. After reducing the maximum CVOC concentrations from over 8,000 ug/L to less than 20 ug/L, the site met the remediation goals and received a No Further Action Letter from NJDEP. For more information and a detailed case study, click here.

Case Study: Key-hole Source Removal

CL-Out aerobic PCE bioremediation in a keyhole treatmentreduced the mass of contamination near the source and down gradient concentrations in the plume. At a former manufacturing facility in Ohio the concentration of PCE near the source was over 100,000 ug/L. Down gradient of the source the PCE concentrations were less than 10% of the source concentration. Aggressive treatment in the source area reduced the source concentration and in the down gradient plume.

Source area concentrations decreased as follows after one treatment with CL-Out bioremediation:

- PCE decreased from 120,000 to 12 ug/L.

- TCE decreased from 2,000 to 12 ug/L

- Cis 1,2-DCE decreased from 9,500 to 8,100 ug/L.

- Vinyl chloride, however, increased from 1,200 to 22,000 ug/L.

The vinyl chloride increased as the aggressive cometabolic treatment stimulated incomplete reductive dechlorination by other naturally occuring organisms.

Down gradient from the source, the concentrations decreased with slight to no increase in daughter products. The down gradient plume had the following results:

- PCE decreased from 5,000 to 1,600 ug/L.

- TCE decreased from 43 ug/L to BDL.

- Cis 1,2-DCE decreased from 140 to 23 ug/L.

- Vinyl chloride was not detected before or after treatment.

Keyhole treatment was a cost effective approach to reducing the mass of contamination in a ground water plume by focusing aggressive treatment on the source area. Concentrations in the rest of the plume decreased as the microbes and treated water dispersed through the plume.

PCE Bioremediation By Aerobic Cometabolism

CL-Out is a consortium selected for aerobic PCE bioremediation. CL-Out cometabolizes PCE by growing on a simple sugar and producing a metabolic enzyme to degrade PCE. The microbes produce a dioxygenase enzyme that breaks the carbon bond in PCE. This reaction eliminates the biproducts of reductive dechlorination. Also, the synergistic effect of the CL-Out consortium cometabolizes the full suite of chloroethenes and chloroethanes.

Click here to learn more about CL-Out bioremediation.

Case Study: Aerobic Cometabolism of TCE and 1,4-Dioxane

In a pilot study to compare aerobic cometabolism with anaerobic reductive dechlorination to remediation TCE and 1,4-dioxane at a former industrial facility in New Jersey, aerobic cometabolism reduced the concentrations of both compounds while anaerobic reductive dechlorination was unsuccessful. For aerobic cometabolism, CL-Out microbes were injected into the aquifer to a depth of 60 to 90 feet below ground. The pilot treatment area was 500 square feet. Monitoring wells were placed upgradient, sidegradient and downgradient of the injection point. Ground water samples were taken on a monthly basis for 9 months.

The results showed that complete TCE mineralization, without the production of daughter products, was measured within the first month. CL-Out bioremediation removed 80% of the TCE at 40 feet downgradient in less than three months. CL-Out bioremediation reduced the 1,4-dioxane concentration to below detection limits at 20 and 40 feet downgradient in the first month.

Click here to view a summary case study.