What is Bioremediation?

Contact us for free consultation and cost estimates.

Bioremediation is the removal of environmental contamination by microorganisms. Bioremediation includes biostimulation of the natural organisms to improve the rate of contaminant removal and bioaugmentation, which introduces beneficial microbes into the contaminated soil or water.

Bioremediation is possible because microorganisms use contaminating chemicals as a food source. By metabolizing the contamination, the microorganism extracts energy as chemical bonds are broken and uses elements of the chemical compounds to build cell parts. The chemical break down may be a partial biodegradation of the chemical or may be complete reduction to the basic minerals of the chemical.

For example, a simple petroleum component like benzene may be completely mineralized into carbon dioxide and water (chemical equation). A larger aliphatic petroleum molecule may be reduced by partial biodegradation by the sequential removal of the terminal carbon group. Either approvach may reduce the toxicity of the chemical or may accelerate further degradation.

CL Solutions provides beneficial microbes in consortia for efficient removal of a wide range of environmental contaminants. The microbes in our consortia have been selected from naturally-occurring sources for their ability to utilize the contaminants for energy and cell structure building. Bioaugmentation with CL Solutions’ consortia may increase the cell population in the contaminated soil or water from a natural level or 1,000 cells per milliliter or milligram to over 1 million cells per milliliter or milligram. Increasing the number of beneficial microbes in the contaminated media increases the rate of contaminant removal.

CL Solutions consortium for petroleum bioremediation, Petrox, includes different organisms that can completely mineralize petroleum compounds to carbon dioxide and water. The synergistic organisms in Petrox have multiple metabolic pathways of breaking down the wide range of organic chemicals in petroleum.

CL Solutions blends a similar consortia of microbes into CL-Out for the cometabolism of hard-to-degrade chemical contaminants such as dry cleaning and industrial solvents. Cometabolism is a way microbes derive energy from degrading one chemical while producing enzymes that degrade other chemicals. With CL-Out cometabolism a sugar is added to support the microbial population while it produces an oxygenase enzyme that breaks down solvents.

How fast is it?

Petrox bioremediation begins as soon as the microbes contact the contamination. Contaminant removal rates have been observed at over 1.0 mg/L/day. Measurable field results may take time as the microbes and effect must migrate from the application location to the sampling location.

CL-Out bioremediation begins as soon as the microbes are in contact with the contamination. Contaminant removal rates results are observed at over 1.0 mg/L/day. In situ results may appear to be lower because it takes time for the microbes and the effect to move from application location to the monitoring location. At most sites the contaminant removal rate is 90% in less than 90 days.

How do bioremediation microbial populations grow in soil and ground water?

Under the right conditions, native microbes may metabolize organic contaminants. Remediation under these conditions is called monitored natural attenuation. The microbial population may be in a lag phase (1) of the growth curve where the population is relatively low. If the natural degradation rate is too slow, nutrients or other amendments may be added to the soil or ground water. This biostimulation can push the population into the log phase (2) of exponential growth. Bioaugmentation is the introduction of microbes grown in the lab into the soil or ground water. The population is injected at the high population of the stationary phase (3)of microbial growth. After the organic contaminants are removed or ecological conditions change, the population enters the decline phase (4).

What microbes metabolize petroleum?

Petroleum is a naturally-occurring substance, so it is not surprising that many organisms have evolved the capability of metabolizing components of petroleum. The most common is Pseudomonas sp., which the most common group found in contaminated soil and ground water. Petrox ® is a consortium of strains of Pseudomonas sp. Other common petroleum metabolizing organisms are Achromobacter, Arthrobacter, Micrococcus, Nocardia, Vibrio, Acinetobacter, Brevibacterium, Corynebacterium, Flavobacterium, Candida, Rhodotorula, and Sporobolmyces.

Can bioremediation remove naphthalene?

Naphthalene is often a recalcitrant petroleum compound that keeps sites from clean closure. This resistance to remediation is due to naphthalene’s relative high adsorption and low solubility rates. Naphthalene has an aqueous solubility of 3.1E1 mg/l compared to benzene at 1.75E3 mg/l . Naphthalene has an affinity of adsorption expressed as the octanol/water partition coefficient (log Kow) of 3.26, while benzene has a log Kow of 2.13. For further comparison, acetone has a high water solubility at 1E6 mg/l and low log Koc of -0.24. In a study of relative degradation rates, the USEPA found a first order kinetic constant of 14.0 L/hg for naphthalene and 0.234 for benzene in activated sludge. Despite these challenges, naphthalene bioremediation with Petrox microbes has been successful at many spill sites.

Microbes initiate metabolism of naphthalene by inserting two oxygen atoms into the naphthalene structure. This initial step is catalyzed by naphthalene dioxygenase. Tests of sites inoculated with Petrox microbes show naphthalene dioxygenase concentrations at 1E8 to 1E10.

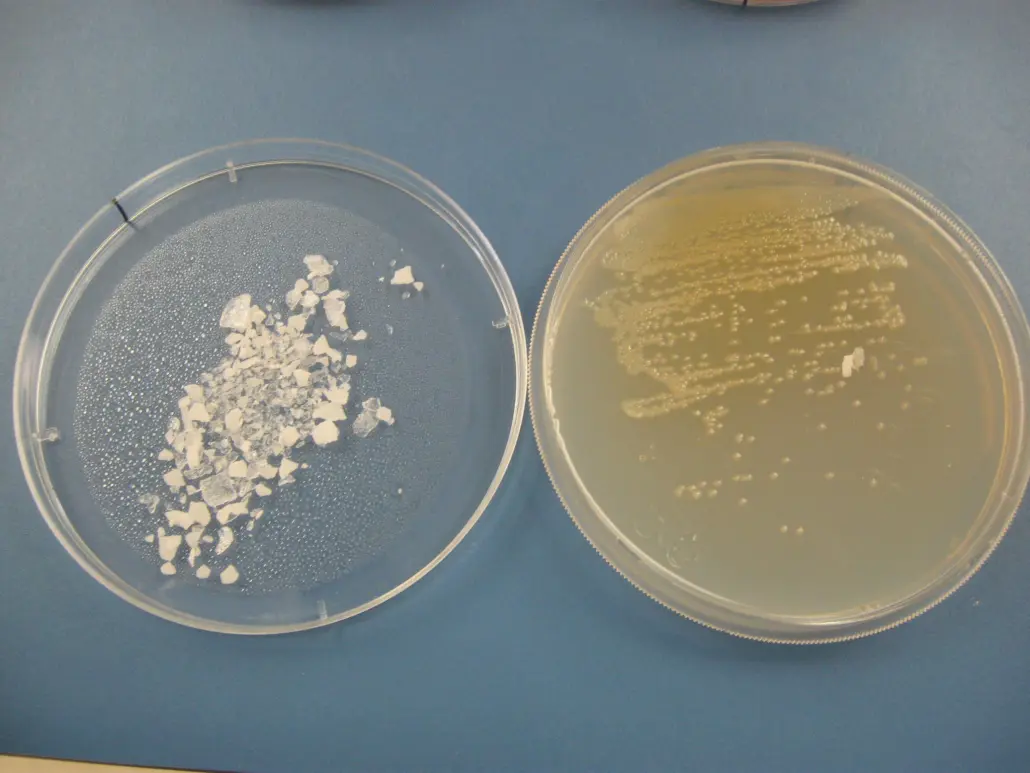

Petrox microbes thrive on naphthalene to the extent that naphthalene is occasionally used in the QA/QC process to verify Petrox viability and effectiveness. In this test, the Petrox organisms are placed on an agar devoid of a carbon source. The naphthalene is applied to the top plate as the sole carbon source. The Petrox viability is then demonstrated by colony growth on the top plate as shown on the following picture.

Addtional information and cases studies may be found here.

What is land farming?

Land farming is the treatment of contaminated soil by excavation and addition of amendments to remove the contaminants. Ammendments are added to the soil in stockpiles or windrows. The ammendments can be microbes for bioremediation, nutrients to promote micorbial growth, or chemicals to react with the contaminants. After the contaminants are removed the soil is returned to the original excavation or used elsewhere.

The main advantage of land farming is improvement of distribution of ammendments over in situ treatment. The soil may be treated with ammendments and mixed to blend the ammendments throughout the soil.

Petrox has been used at many sites to remove petroleum from contaminated soils. For example, Petrox microbes were added to excavated petroleum-contaminated soil to accelerate the degradation of DRO and ERO total petroleum hydrocarbons at an industrial redevelopmnet site in Chicago. Petrox was added by spraying the surface of the soil with a hydrated Petrox solution. The microbes were mixed into the soil using a tractor-mounted disc tiller.

After approximately 60 days, soil samples were taken for testing. The soils showed 90% to 99% petroleum removal. The following chart shows the range of DRO and ERO concentrations before and after Petrox treatment.

Petrox has also been used to treat pesticides by land farming at a site in California. The soil contamination consisted of pesticides including 4,4-DDD, 4’4-DDE and toxaphene. Soil samples were sent to CL Solutions for bench-scale treatability studies. The following table shows the maximum detected concentrations and the treatment results.

Contaminant |

Untreated Concentrations (ug/Kg) |

Post-treatment concentrations (ug/Kg) |

4,4-DDD |

390 |

250 |

4,4-DDE |

380 |

220 |

Toxaphene |

8,500 |

440 |

After the bench-scale verification, full-scale bioremediation was implemented. The contaminated soil was placed in two stockpiles and treated with Petrox. The following table shows the pre- and post-treatment results.

Contaminant Concentrations (ug/Kg) |

||||

Contaminant |

Pile 1 |

Pile 2 |

||

Before |

After |

Before |

After |

|

4,4-DDD |

310 |

170 |

14 |

nd ( <5) |

4,4-DDE |

810 |

300 |

8.7 |

nd (<5) |

Toxaphene |

12,000 |

7,300 |

380 |

nd (<5) |

Conclusions

The Petrox treatment successfully reduced the concentrations of pesticide contaminants in the soil stockpiles. For additional information or assessment of applicability to your site contact CL Solutions.

Is Perchlorate Biodegradable?

Perchlorate is biodegradable as an electron acceptor. Under aerobic conditions a substrate is added to the aquifer and metabolized to remove oxygen and nitrate first. Perchorate is next in line as the available electron acceptor.

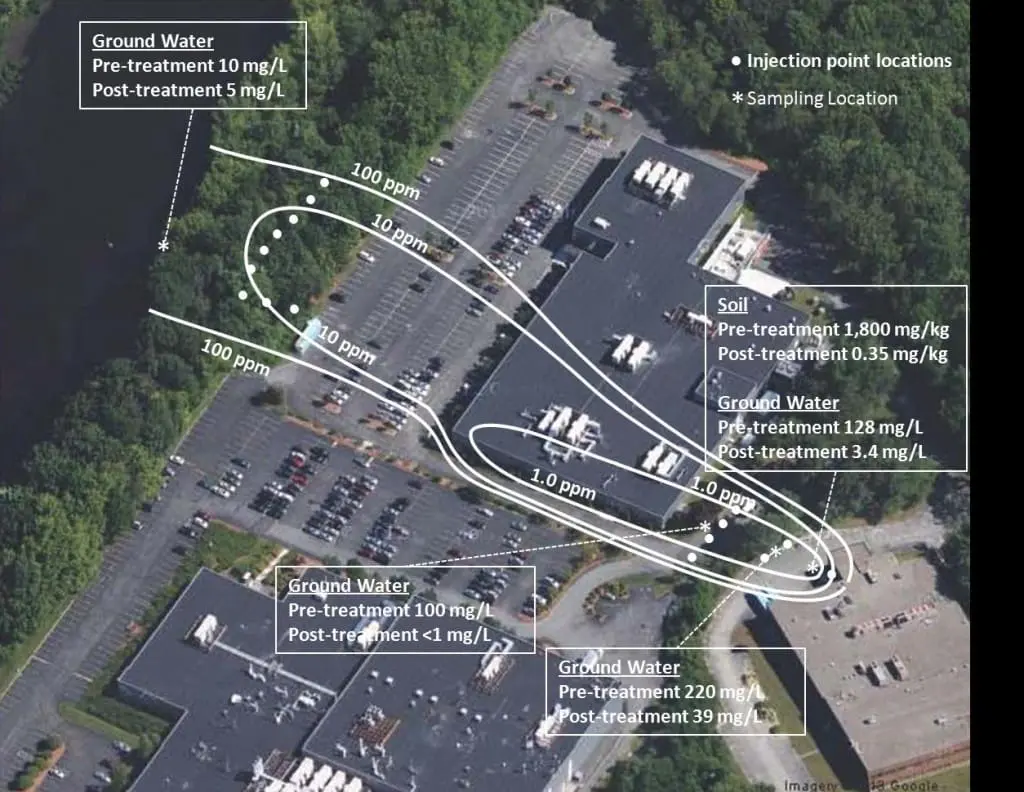

CL-Out® bioremediation was implemented at a confidential manufacturing site to remediate nitrate and perchlorate concentrations in soil and ground water. The consultant installed a pump and treatment system that was operated for several years in immediate response to the discovery of contamination. While perchlorate was the primary contaminant, the ion-exchange resin became quickly saturated with nitrate, which was present at much higher concentrations than the perchlorate. After review of various options and completion of a bench-scale test, the consultant implemented in situ CL-Out bioremediation to reduce the on-going cost of ground water extraction and treatment.

One of the key factors in CL-Out® cometabolism of perchlorate at this site was that CL-Out® organisms were able to reduce sequentially the oxygen and nitrate prior to perchlorate. The initial nitrate concentrations were much higher than the perchlorate concentrations and pre-maturely saturated the ion-exchange resin. The perchlorate concentration did not decrease until the nitrate concentration decreased to less than the perchlorate concentration. One of the benefits of the CL-Out® organisms was this ability to utilize these different electron acceptors.

The initial application of CL-Out to the soil reduced the perchlorate source concentration. After eight months of ground water bioremediation, the perchlorate concentration in the unconsolidated aquifer decreased from 128 mg/L to 3.4 mg/L immediately down gradient of the source area and from 220 mg/L to 39 mg/L farther down gradient.

Simultaneously, the CL-Out® microbes also removed the nitrate. Down gradient of the source area the nitrate concentration decreased from 105 mg/L to <1.0 mg/L. Farther down gradient the nitrate concentration decreased from 200 mg/L to 5 mg/L.

Bioremediation of perchlorate using CL-Out has been recognized as a sustainable green technology. It has the added benefit of reducing costs and accelerating remediation to save time.

Following the ASTM standards greener remediation best management practices, Irwin Engineering of Boston, Massachusetts saved time and money for their client in the removal of nitrate and perchlorate contamination using CL-Out bioremediation. Most of the savings came from switching from ground water extraction and treatment using ion-exchange to in situ bioremediation.

Using best management practices saved the following amount of money:

Overall project savings $3 to $5 million.

Overall time savings 3 to 5 years.

The property was sold to a new owner and transferred without impairment.

How to Assess a Site for Bioremediation

Sucessful bioremediation is influenced by many factors, but a few site characteristics determine whether a site is a reasonable candidate for bioremediation. These characteristics are whether the geochemistry of the site will support microbial growth and whether there is sufficient permeability for complete and uniform distribution of micorbes or ammendments.

Some of the factors that influence permeability are:

Some of the geochemical factors that influence the microbial growth environment are:

Pilot studies can answer questions about the applicability of bioremediation to a particular site. A pilot study can verify the survivability of microbes applied under bioaugmentation. A pilot study can also provide information on post injection distribution of the microbes.

As conditions inevitably change during remediation, a pilot study can determine what geochemical changesmay occur during full-scale treatment.

Bench scale studies may also be beneficial, but cannot replicate actual field conditions.

What is "Land Farming" for Environmental Remediation

Land farming is a technique of soil remediation that reduces the uncertainty of in situ treatment. Under land farming, the contaminated soil is excavated and placed on the ground surface, usually with an impermeable barrier below the contaminated soil. Chemical ammendments or micorbes are added to the soil to neutralize or destroy the contaminants.

Bioremediation using Petrox was used to remove petroleum contamination from soil at an industrial site in Chicago. Petrox microbes were added to excavated petroleum-contaminated soil to accelerate the degradation of DRO and ERO total petroleum hydrocarbons. Petrox was added by spraying the surface of the soil with a hydrated Petrox solution. The microbes were mixed into the soil using a tractor-mounted disc tiller. After approximately 60 days, soil samples were taken for testing. The soils showed 90% to 99% petroleum removal.

Petrox bioremediation was used to remediate pesticide-contaminated soil at an industrial location in California.

The soil contamination consisted of pesticides including 4,4-DDD, 4’4-DDE and toxaphene. Soil samples were sent to CL Solutions for bench-scale treatability studies. The following table shows the maximum detected concentrations and the treatment results.

Contaminant |

Untreated Concentrations (ug/Kg) |

Post-treatment concentrations (ug/Kg) |

4,4-DDD |

390 |

250 |

4,4-DDE |

380 |

220 |

Toxaphene |

8,500 |

440 |

After the bench-scale verification, full-scale bioremediation was implemented. The contaminated soil was placed in two stockpiles and treated with Petrox. The following table shows the pre- and post-treatment results.

Contaminant Concentrations (ug/Kg) |

||||

Contaminant |

Pile 1 |

Pile 2 |

||

Before |

After |

Before |

After |

|

4,4-DDD |

310 |

170 |

14 |

nd ( <5) |

4,4-DDE |

810 |

300 |

8.7 |

nd (<5) |

Toxaphene |

12,000 |

7,300 |

380 |

nd (<5) |

The Petrox treatment successfully reduced the concentrations of pesticide contaminants in the soil stockpiles. For additional information or assessment of applicability of landfarming to your site contact CL Solutions.

Can Bioremediation Work at Dry Cleaners?

Dry cleaner property may be contaminated by dry cleaning solvents, which are historically mainly stoddard solvent or tetrachloroethylene. Stoddard solvent is a petroleum product and may be bioremediated much like fuel contamination at gas stations. Tetrachloroethylene, which is also known as perchloroethylene, PCE, or perc, is more difficult to bioremediation than stoddard solvent, but may be subject to bioremediation by two types of micorbes. Under oxygen-poor conditions, anaerobic organisms may be used to degrade and remove PCE and it’s breakdown products. Under oxygen-rich, conditions, aerobic microbes successfully remove PCE by cometabolism.

CL Solutions provides CL-Out for the remediation of PCE contamination at dry cleaners. While metabolizing a sugar substrate, the CL-Out organisms produce mono- and dioxygenase enzymes that bridge the carbon bond to destabilize the compound. The solvent is converted to an organic acid that the organism can metabolize. View the degradation pathway. The benefit is that CL-Out bioremediation can be applied to soils both in situ and ex situ.

CL-Out cometabolism uses a dioxygenase enzyme that is produced constituatively as the metabolic substrate is consumed. The dioxygenase enzyme destabilizes the carbon bond in the PCE to convert the molecule to an organic acid that leads to complete mineralization. Click here to view the PCE and TCE cometabolic degradation pathways. Click here to find out more about CL-Out bioremediation.

Is Bioremediation Effective on Styrene?

Researchers have shown that styrene contamination may be removedby bioremediation. There are many micorbes that can utilize styrene as a metabolite,meaning they breakit down for energy and cellular material. The microbes in Petrox are among those types shown to be effective in bioremediating styrene. Petrox, however, has not been used in the field application of styrene bioremediation. CL Solutions welcomes the opportunity to demonstrate Petrox bioremediation of styrene in feld pilot andfull-scale applications.

CL Solutions provides two main product lines – CL-Out for bioremediation of chlorinated solvents by aerobic cometabolism and Petrox for direct metabolism of petroleum hydrocarbons. Both products are safe for human health and the environment. They have been used at hundreds of sites across the US and Canada.

How much Oxygen in Needed for Aerobic Cometabolism of PCE?

/in Chlorinated Solvent Remediation/by Mike SaulAerobic Cometabolism of PCE CL-Out bioremediation degrades PCE without the production of vinyl chloride under a wide aerobic range. The degradation pathway is via organic acids. The following compilation of data from 14 locations shows PCE removal with ORP levels in ground water ranging from -150 to 250 standard units. The concentration removed PCE concentrations […]

Vinyl Chloride Bioremediation in Central Ohio

/in Chlorinated Solvent Remediation/by Mike SaulAerobic Cometabolism of Vinyl Chloride CL-Out® bioremediation removed vinyl chloride and other chlorinated solvents found in ground water at a former automobile repair shop near Columbus, Ohio. The solvents were thought to have been released from an underground storage tank (UST). After the UST and associated contaminated soil were removed, CL-Out bioremediation was implemented to […]

How Sustainable Green Remediation Saves Time And Money

/in Chemical Industries, CL-Out/by Mike SaulCL-Out Bioremediation Wins Green Remediation Recognition and Saves Time and Money Sustainable, green remediation is recommended to reduce the environmental impact of the removal of existing soil or groundwater contamination. It has the added benefit of reducing costs and accelerating remediation to save time. Following the ASTM standards greener remediation best management practices, Irwin Engineering […]

CL-Out Bioremediation of Ground Water in Clay Soils

/in Chlorinated Solvent Remediation, CL-Out, Dry Cleaners/by Mike SaulSuccessful In Situ Remediation in Low Permeability CL-Out bioremediation of groundwater in clay soils reduced concentrations of PCE and TCE at a former dry cleaners in Moline, Illinois. In just over 2 weeks after injection, CL-Out microbes cut the contaminant concentrations in half. PCE from 62.2 to 25.6 mg/L TCE from 11.2 to 6.0 mg/L […]

Photographs of Field Applications of Bioaugmentation

/in CL-Out, News, Petrox/by Mike SaulThese photographs show actual field applications of CL-Out and Petrox.

What is MEOR?

/in News, Petrox/by Mike SaulMEOR is microbial enhanced oil recovery. Some microbes produce biosurfactants that increase the water-solubility of oil. The biosurfactants’ benefit microbes by making it easier for the microbes to metabolize oil. Additionally, the biosurfactants can strip oil from rock and soil surfaces to improve environmental remediation by extraction, air stripping, or sparging. The Pseudomonas sp. in […]