Bioremediation Restores Property Value

CL-Out bioremediation has been used to restore the environmental conditions and property value at many dry cleaner locations. Dry cleaner remediation with CL-Out microbes saves time and money by working with the natural site conditions and using a high population of known beneficial microbes. Site closure often occurs in a matter of weeks or months versus several years or more for other methods, giving users the combined benefit of fast site closure and remarkable cost savings.

Greener, Sustainable Remediation

CL-Out aerobic bioremediation PCE and TCE is a sustainable process for soil and ground water remediation. As these compounds are not directly metabolized under aerobic conditions, the competitive advantage goes to the CL-Out organisms that cometabolize them. While utilizing a sugar substrate, the CL-Out organisms produce mono- and dioxygenase enzymes that bridge the carbon bond to destabilize the compound. The solvent is converted to an organic acid that the organism can metabolize. View the degradation pathway. The benefit is that CL-Out bioremediation can be applied to soils both in situ and ex situ.

How CL-Out Bioremediation Works

CL-Out cometabolism uses a dioxygenase enzyme that is produced constituatively as the metabolic substrate is consumed. The dioxygenase enzyme destabilizes the carbon bond in the PCE to convert the molecule to an organic acid that leads to complete mineralization. Click here to view the PCE and TCE cometabolic degradation pathways.

CL-Out is a consortium of naturally-occurring microbes. The microbes have the benefits of metabolic diversity and environmental stability. They are non-pathogenic and safe for human health and the environment. Click here to find out more about CL-Out bioremediation.

Case Study: Dry Cleaner Bioremediation Pilot Study Results

A CL-Out bioremediation pilot study confirmed that aerobic PCE cometabolism removed dry cleaning solvent contamination from ground water. At the dry cleaner site, the PCE in ground water was 27 parts per billion (ppb). Bioaugmentation introduced CL-Out microbes and dextrose as the metabolic substrate by injection into the ground water up gradient from the sentinal monitoring well. After 30 days the PCE concentration decreased to 20 ppb. After 6 months the PCE concentration decreased to 16 ppb.

As the PCE was decreasing, the site conditions stayed aerobic. The dissolved oxygen level in ground water decreased from 1.07 to 0.71 mg/l. Meanwhile, the ORP decreased from 99 to 45 mv. These aerobic aquifer conditions support the conclusion that the PCE removal was through aerobic bioremediation.

Case Study: Industrial Dry Cleaner Remediation

Site Summary

A CL-Out bioaugmentation pilot study verified the applicability of CL-Out remediation of an industrial dry cleaning site. The pilot study also determined whether the availability of oxygen to support cometabolism would limit the bioremediations.

Geology and Hydrology

Although the impacted ground water was relatively shallow, the site geology was complicated and varied across even this small site. In general the glacial deposits at the site were mainly till with interbedded sandy and silty zones. The impacted ground water was contained within the granular deposits.

Contamination

The main ground water contaminant was PCE with lower concentrations of TCE, cis -1,2 DCE and vinyl chloride. In the pilot study area, the PCE concentration was 44,200 μg/L and the total of the daughter products was 14,750 μg/L.

Pilot Study Design

A pilot study was completed in the source area in the fall of 2009. One unit of CL-Out was injected into the affected ground water in the source area. One unit of CL-Out is a 55-gallon slurry with a microbial concentration of 109 cfu/ml. The CL-Out microbes were injected with 50 pounds of dextrose to provide a carbon source to support the energy requirements of the population. Pre- and post -treatment samples were taken on February 19 and December 10, 2009. The post-treatment sample was taken after the monitoring well was purged of the injected volume. The following table shows the contaminant concentration trends in the treatment area.

Results

The pilot study verified the applicability of CL-Out bioremediation to the site. The total concentration of CVOCs was reduced from 59,000 to 13,740 μg/L. The CL-Out bioremediation was most effective in the removal of PCE and TCE. There was an increase in vinyl chloride suggesting some incomplete reductive dechlorination, probably by native dehalogenating organisms. Full-scale treatment will be most effective with the addition of an oxygen supplement to limit the dehalogenation and promote the cometabolism of the daughter products. Overall the push-pull pilot study verified the effectiveness of CL-Out bioremediation and provided insights for making full-scale application more effective.

Case Study: CL-Out Completes Dry Cleaner Remediation After Stalled Natural Attenuation

Investigation of an industrial dry cleaners near Philadelphia, Pennsylvania found concentrations of breakdown products of PCE in the soil and ground water. The parent PCE presumably was reductively dechlorinated to TCE, DCE and vinyl chloride. However, since the daughter products DCE and vinyl chloride are more readily degraded under aerobic conditions, the breakdown was incomplete and natural attenuation stalled. CL-Out was applied with an oxygen supplement to complete the remediation under aerobic conditions favorable for DCE and vinyl chloride bioremediation.

Geology

The geology of the property is interbedded sandy silt, silt and clay layers. The contamination was found in a shallow silty sand formation that is underlain by a dense clay layer. A sand layer directly beneath the clay layer was unaffected by the contamination in the upper sand.

Hydrogeology

The perched ground water was within a fill layer, so the hydraulic conductivity was expected to be variable. Slug testing results showed the hydraulic conductivity in the upper sand ranged from 1.1 to 3.9 ft/day. The ground water flow direction was consistently toward a local surface stream. The extent of the contamination plume was approximately 10,000 square feet.

Ground Water Contamination

The contaminants found at the site were mainly TCE and DCE with trace levels of vinyl chloride. This suite of contaminants indicated that there was natural degradation of the PCE to lesser halogenated compounds. The maximum concentrations prior to bioaugmentation were 220 ug/L of DCE, 9.2 ug/L of TCE and 31 ug/L of vinyl chloride.

Remediation

CL-Out was introduced into the ground water through one-inch diameter tubing installed using a direct push sampler. The use of small diameter injection points made the remediation possible without disruption the dry cleaner operations. Three injection points were installed in the high concentration area. Additional injection was made in places where shallow soil had been excavated.

The CL-Out injection was a dosing of four drums in December 2005.

Results

Three months after the injection of CL-Out, the DCE concentration dropped from 200 to 54 ug/L. The vinyl chloride concentration decreased from 31 to 11 ug/L. After seven months the TCE and vinyl chloride concentrations were below detection limits and the DCE concentration decreased to 2.9 ug/L.

Due to the relatively anoxic conditions, an oxygen supplement was added to support the aerobic cometabolism. During the active treatment the dissolved oxygen levels increased from 1.9 to 8.5 mg/L. The CL-Out microbial population was maintained at 200,000 cells per milliliter.

The monitoring results suggest that by supplementing the dissolved oxygen levels, the CL-Out population was maintained for an extended period. The extended peak of CL-Out population made possible a greater level of contaminant removal.

Case Study: Shopping Center Dry Cleaner Remediation Restores Value

A history of spills and/or releases at two adjacent dry cleaning facilities near Houston, TX, resulted in significant soil and shallow groundwater contamination with PCE and daughter products. Soil was relatively permeable, with rapid groundwater flow beneath the site. A long, narrow, off-site plume extended beneath a residential neighborhood. Chemical oxidation was employed initially with only limited success in the areas of highest contamination. To take advantage of the soil permeability and other site conditions, the response action was amended to include enhanced aerobic bioremediation by cometabolism. Specialty microbes were introduced into the plume in several injections over a 15-month period. This approach achieved total contaminant level reductions in the source area from 1,600 to less than 40 µg/L, and at the front edge of the plume, levels decreased from 500 to 5 µg/L.

For the full case study click here:

Case Study: CL-Out Dry Cleaners Remediation Quickly Restores Property Value

Historical operations at a Houston area dry cleaners resulted in a chlorinated solvent plume (perchloroethylene or PCE) in the shallow ground water. Permeable shallow soil at the site allowed rapid vertical migration at the source and lateral migration in the shallow ground water. This migration resulted in an off-site migration of the plume beneath an apartment complex causing concern for potential vapor intrusion hazards; as well as, a decrease in property value.

A ground-water extraction and treatment system was installed to address the

dissolved phase concentrations. The system reduced the total volatile organic compound

(VOC) concentration in the source area from 115,400 to 36,500 µg/l. However, over

time, operating maintenance and cost escalations were exceeding the on-going remedial

benefit. The system was shut down after nine years of operation.

A review of available remedial technologies that could be implemented within the physical constraints of the

site was conducted. In-situ enhanced aerobic bioremediation was selected to address the

remaining ground-water concentrations because of the permeability of the formation, the

relatively aerobic conditions, and the benefit of reducing the risk of VC accumulation. View the aerobic cometabolic degradation pathway.

Click here for a link to the full report from the 2007 Battelle Conference on Bioremediation

Case Study: CL-Out Bioremediation of Groundwater in Clay Soils

CL-Out bioremediation of groundwater in clay soils reduced concentrations of PCE and TCE at a former dry cleaners in Illinois. In just over 2 weeks after injection, CL-Out microbes cut the contaminant concentrations in half.

- PCE from 62.2 to 25.6 mg/L

- TCE from 11.2 to 6.0 mg/L

- Cis 1,2-DCE from 3.8 to 1.2 mg/L

- Vinyl chloride less than 0.001 mg/L before and after treatment

The remediation continues as the microbes grow and cometabolize the residual contamination. Even in tight clay soils the aerobic cometabolism remediates dry cleaning solvents without producing vinyl chloride or other dangerous by products.

Case Study: Push-Pull Application For Dry Cleaner Remediation

A CL-Out bioremediation push-pull pilot study was implemented at a confidential dry cleaners site to verify the applicability of CL-Out bioremediation.

One unit of CL-Out was injected into the affected ground water in the source area. One unit of CL-Out is a 55-gallon slurry with a microbial concentration of 1,000,000 cfu/ml. The CL-Out microbes were injected with 50 pounds of dextrose to provide a carbon source to support the energy requirements of the population. The post-treatment sample was taken after the monitoring well was purged of the injected volume.

The pilot study verified the applicability of CL-Out bioremediation to the site. The total concentration of CVOCs was reduced from 59,000 to 13,740 µg/L.

Case Study: Fast Dry Cleaner Bioremediation

Fast dry cleaner bioremediation by CL-Out microbes reduced PCE concentrations in ground water by more than 99% in less than 90 days to achieve GCTL standards at a dry cleaners in Florida. The naturally aerobic aquifer conditions supported this aerobic cometabolism of PCE.

It is observed at many sites that naturally aerobic conditions prevent the natural reduction of PCE and TCE. This is obvious when the suite of contaminants include high concentrations of PCE or TCE without daughter products. Instead of working against the natural conditions to drive the aquifer conditions anaerobic to facilitate reductive dechlorination, a more sustainable approach is to use CL-Out aerobic cometabolism to remove the parent compounds without producing daughter products. This approach has been used at hundreds of sites such as this example in Florida.

Case Study: CL-Out Bioaugmentation Saves Time and Money

By switching from active extraction to in situ CL-Out® bioremediation, In Control Technologies, Inc. of Houston, Texas saved their client $100,000s in on-going operation and maintenance costs. The Site was a shopping center where soil and ground water were contaminated by dry cleaning chemicals. A dual phase extraction system was installed and operated for 9 years. The dual phase system reduced the total CVOCs by 70%, but the contaminant removal rate reached the limit of cost effectiveness.

By switching to bioremediation, the client avoided $75,000 on-going annual operation and maintenance cost with a $20,000 investment in bioremediation. CL-Out® bioremediation reduced the residual contamination by more than 98% in less than 90 days. This case study was reported at the 9th In Situ and On-Site Bioremediation Symposium, 2007

Case Study: Vermont Dry Cleaner Remediation Using CL-Out

Cl-Out bioremediation was used to remove PCE from ground water at a dry cleaners in Vermont. CL-Out micorbes were selected for bioremediation of the site because they are compatible with the natural aerobic aquifer conditions. One application of CL-Out bioaugmentation reduced the PCE concentration by 90% in less than 6 months without increasing the vinyl chloride concentrations.

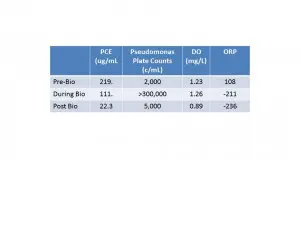

The following table summarizes the process of aerobic cometabolism of PCE. The pre-bioaugmentation sampling showed aerobic conditions and a low population of Pseudomonas microbes. After bioaugmentation the Pseudomonas population was higher. As the microbes consumed the dextrose substrate and produced the oxygenase enzymes necessary for PCE destruction, the ORP and PCE concentrations decreased. Six months after the bioaugmentation, the microbial population returned to the pre-bioaugmentation conditions.