The Problem

The Solution

Choosing The Right Product For Ex Situ Petroleum Bioremediation

Selecting the right product for ex situ petroleum bioremediation comes down to usability factors. Both Petrox and Custom Blend products quickly degrade petreleum in soil. The average petrolem removal rate for Petrox bioremediation is 68 mg/kg/day. The average removal rate for Custom Blend is 1,315 mg/kg/day. The actual field results can vary depending of the effective distribution if microbes in the soil, field temperature, moisture, soil type and the type of hydrocarbon.

Petrox is a blend of microbes that requires freeze-drying to preserve high microbial yields. Petrox must be kept frozen prior to use and must be hydrated before application to the soil.

Custom Blend microbes are spore-forming organisms and can be stored at room temperature until ready to be used. The Custom Blend microbes should be mixed with water to make the application easier, Custom blend is more suitable for routine use because it can be stored until it is needed.

Case Study: California UST Closure with Petrox Bioremediation

After removal of USTs, piping and surrounding soils, ground water was treated with 110 gallons of Petrox® by direct injection in December 2009. Post-treatment sampling shows that the bioaugmentation reduced the contaminant levels to below regulatory standards by the next semi-annual sampling round.

|

Sampling Date |

TPHg | Benzene | Toluene | Ethylbenzene |

Total Xylenes |

MTBE | |

| Pre-bioaugmentation |

10/6/09 |

1,200 | 320 | 7.2 | 700 |

70 |

5 |

| Post-bioaugmentation |

4/26/10 |

<50 | <0.5 | <0.51 | <1 |

<5 |

<0.5 |

All concentrations shown in µg/L.

Case Study: In Situ LNAPL Sheen Bioremedation

Background

High concentrations of petroleum in the subsurface can accumulate in a separate liquid phase that floats on the water table, which is referred to as light non-aqueous phase liquid (LNAPL). Investigation and characterization of the extent of separate phase petroleum is challenging. In turn, successful remediation, which depends on accurate and complete site characterization, can be equally challenging. In this case study Petrox® bioaugmentation was used to remove LNAPL and dissolved-phase petroleum to achieve No Further Action status.

Geology and Hydrogeology

The site is located in the Georgia Piedmont where the geology is characteristically weathered granite and saprolite. The petroleum was found in layers of interbedded clay, silt and sand. The first water was encountered at approximately 28 feet below ground surface. The hydraulic conductivity based on slug tests of the impacted zone was 10-4 to 10-5 cm/sec.

The ground water aquifer was naturally aerobic. Dissolved oxygen measurements taken from monitoring wells in the source area ranged from 1.9 to 2.1 mg/L. The oxidation-reduction potential (ORP) measured in the same wells ranged from 241 to 283 mv. The aerobic conditions were not typical of petroleum releases, but favored in situ bioremediation.

During the implementation of bioremediation, the region experienced a drought. The water table dropped below the bottom of some of the monitoring well screens for part of the period. Sampling results may have been affected during the drought, but normal ground water conditions were restored and maintained for the final two years of monitoring.

Contamination

The leaking underground storage tank (UST) was removed and a temporary high-vacuum dual phase extraction system was operated for one day in April 2007. Approximately 50 gallons of petroleum was removed by the high vacuum system. After operation of the high vacuum system was discontinued, the source area total benzene, toluene, ethyl benzene and xylene concentrations was more than 143,000 µg/L and 22 inches of separate phase petroleum was found in a monitoring well outside of the former UST cavity.

The remediation goals were to remove the separate phase product and reduce the dissolved phase BTEX concentrations to below in-stream water standards.

Remediation Approach and Results

The remediation approach was combination of in situ Petrox® bioremediation and periodic liquid phase bailing. It was believed that the petroleum was present in a thin layer, but represented itself as a thicker layer in the monitoring well that intersected the layer. The separate phase was bailed out when it was encountered during monitoring events.

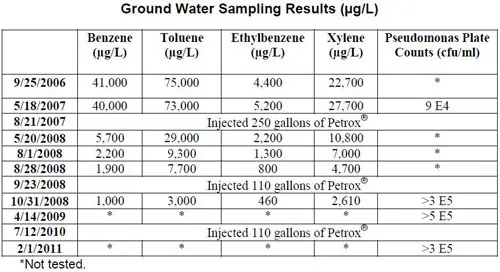

Petrox® bioremediation was used to degrade the petroleum in the ground between the former UST cavity and the impacted down gradient monitoring wells. Petrox® was introduced into the contaminated ground water in three applications by injection through nine temporary well points surrounding the former UST location.

The first injection was 275 gallons of microbial slurry in August 2007. The dissolved phase BTEX concentration decreased by more than 60%. The contaminant concentrations continued to decrease for a year following the first injection. The BTEX concentration was reduced by 90% in that first year. A second injection of 110 gallons of Petrox was completed in September 2008. After one month the BTEX concentrations decreased by 50%. The following table summarizes the treatment and contaminant removal results.

The analysis of ground water samples for Pseudomonas sp. by plate count analysis showed the microbial population increased over background levels. The Petrox population maintained an effective level for bioremediation for 6 months to a year following each application.

The separate phase was reportedly no longer present in 2011 and the site received a No Further Action Status designation.

Conclusions

This project demonstrates the benefits of bioaugmentation for high concentrations of petroleum in ground water. Bioaugmentation delivers very high population of effective petroleum-degrading organisms that can be sustained for a long time. The microbes are compatible with bailing out accumulated separate phase from monitoring wells to accelerate the site closure. The total cost for microbes used to close this site was $8,000.

Case Study: Petrox Bioremediation Prepares Urban Bulk Fuel Facility For Reuse

A 30 acre bulk fuel facility is ready for reuse after remediation of nearly 100,000 tons of petroleum-contaminated soil in an urban setting near Los Angeles. Bulldog Green Remediation of Walnut Creek, California used a proprietary ex situ treatment process combining Petrox organisms in a custom blend to remediate the soils. All soil was treated and reused on site. This closed-loop process eliminated 8,000 truck loads of soil from the roads and landfills in southern California.

The treatment process reduced contaminant concentrations from typical levels of 1,000 to 10,000 mg/kg to less than 100 mg/kg in less than 30 days. This rapid treatment rate made possible continuous cycling from excavation, through treatment, and back filling.

The site is now ready for reuse as a park and other development.

Case Study: Fast Bioremediation Eases Site Development in Boston

Underground storage tank (UST) leaks from a former gas station contaminated shallow ground water under a parking lot for a commercial building. The UST contamination was found during trenching for utilities. As the presence of contamination prevented further property development, fast remediation was important to the stakeholders.

The size of ground water plume that resulted from leaching soil contaminants was estimated to be 5,000 square feet. The contamination was mainly diesel-range petroleum constituents, with the highest concentrations in the aliphatic range, but there were also scattered detections of xylene, toluene, and ethylbenzene.

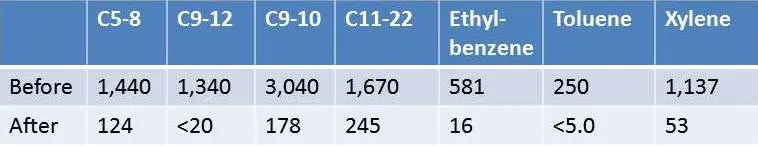

Petrox bioremediation was implemented in the ground water. Three units of Petrox (165 gallons) were injected into the contaminated ground water through vertical injection wells located up gradient of the monitoring wells.

After a single inoculation of Petrox, the contaminant concentrations were reduced across the property. The following table shows the overall reduction in both the volatile and semi-volatile range hydrocarbons.

Case Study: In Situ TPH Bioremediation

With Petrox microbes, in situ TPH bioremediation reduced the concentration of petroleum in soil at a former gas station from 9,500 mg/kg to 52 mg/kg. The impacted soil was at more than 20 feet deep. Injection of calcium peroxide provided the oxygen needed for metabolism of the petroleum by Petrox microbes. The post treatment sampling was 90 days after the bioaugmentation, so that even though the average remediation rate was 105 mg/kg/day, the peak remediation rate must have been much higher when the Petrox population was higher.

This is another example of fast, reliable bioremediation by Petrox organisms.

Case Study: Petroleum Spill Bioremediation

After removal of USTs, ground water was treated over a one-half acre plume in Houston, Texas. Petrox bioaugmentation was implemented by injection of 110 gallons of high concentration microbial solution in April 2006. Post-treatment sampling shows the bioaugmentation significantly reduced the source area contaminant levels at a cost of less than $2,000 for the Petrox®.

| Sampling Date | Benzene | Toluene | Ethylbenzene | Total Xylenes | |

| Pre- bioaugmentation | 4/4/06 | 2,000 | 1,400 | 1,600 | 2,460 |

| Post- bioaugmentation | 8/9/06 | 350 | 240 | 470 | 69 |

All concentrations shown in µg/L.

Case Study: In situ Heavy Oil Bioremediation in Alberta

Using a special microbial blend, Delta Environmental has been successfully bioremediating high concentrations of heavy oil in soil around pipelines and oil production equipment. At a typical site, Delta reduced the concentration of petroleum C34 to >C50 from 130,000 mg/Kg to less than 10,900 in 30 days. That is a removal rate of 3,970 mg/Kg/day. This approach not only benefits the environment and meets green cleanup standards, but saves money and equipment downtime for the facility.

Case Study: Land Farming Accelerates Bioremediation

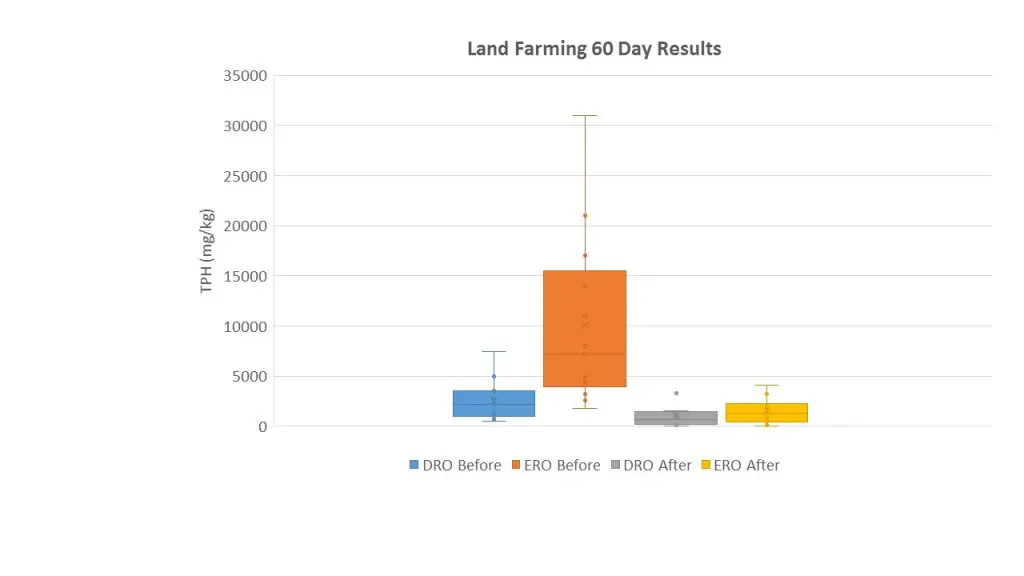

Petrox microbes were added to excavated petroleum-contaminated soil to accelerate the degradation of DRO and ERO total petroleum hydrocarbons. Petrox was added by spraying the surface of the soil with a hydrated Petrox solution. The microbes were mixed into the soil using a tractor-mounted disc tiller.

After approximately 60 days, soil samples were taken for testing. The soils showed 90% to 99% petroleum removal. The following chart shows the range of DRO and ERO concentrations before and after Petrox treatment.

Petroleum Bioremediation in Produced Water

CL Solutions provides a special consortium of microbes for oil-contaminated water treatment. Under various conditions, the oil removal rate was as much as 1,300 mg/L/day. In some situations the remediation goal is simply to remove the visible sheen or separate-phase oil. With aeration, CL Solutions microbes were able to remove the visible oil layer and reduce the TPH concentration from 29% to less than 1% in 30 days at a waste oil lagoon. For more information and other case studies click here.

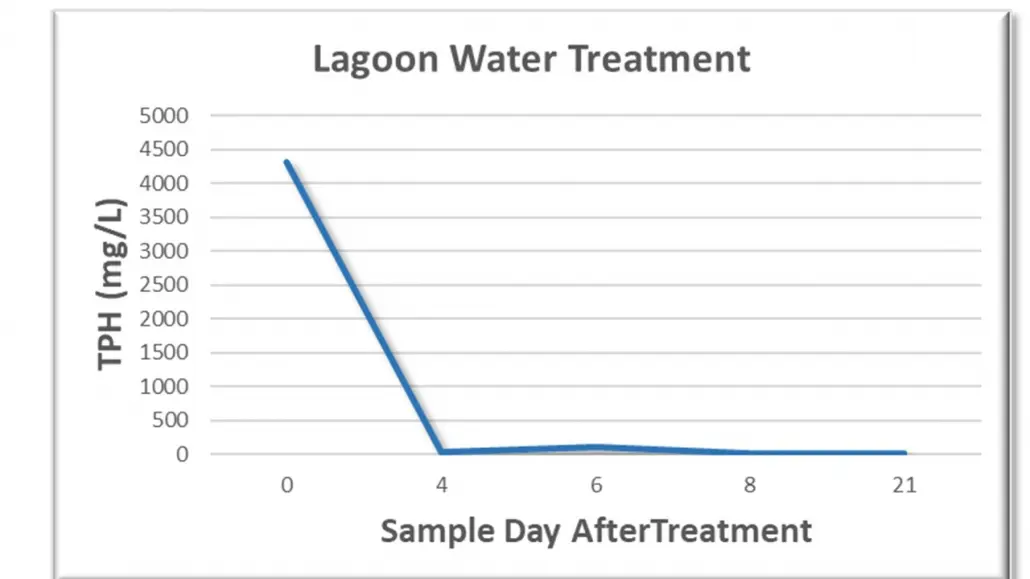

Petroleum Bioremediation in a Lagoon Spill

Delta Remediation of Alberta, Canada remediated an accidental release of petroleum into a wastewater treatment lagoon using Biologix, which is a specialty blend of micorbes provided by CL Solutions. The TPH concentrations were reduced from 4,300 mg/L to 32 mg/L in 4 days.

Photographs of the lagoon before and after bioremediation of TPH spill using Biologix.