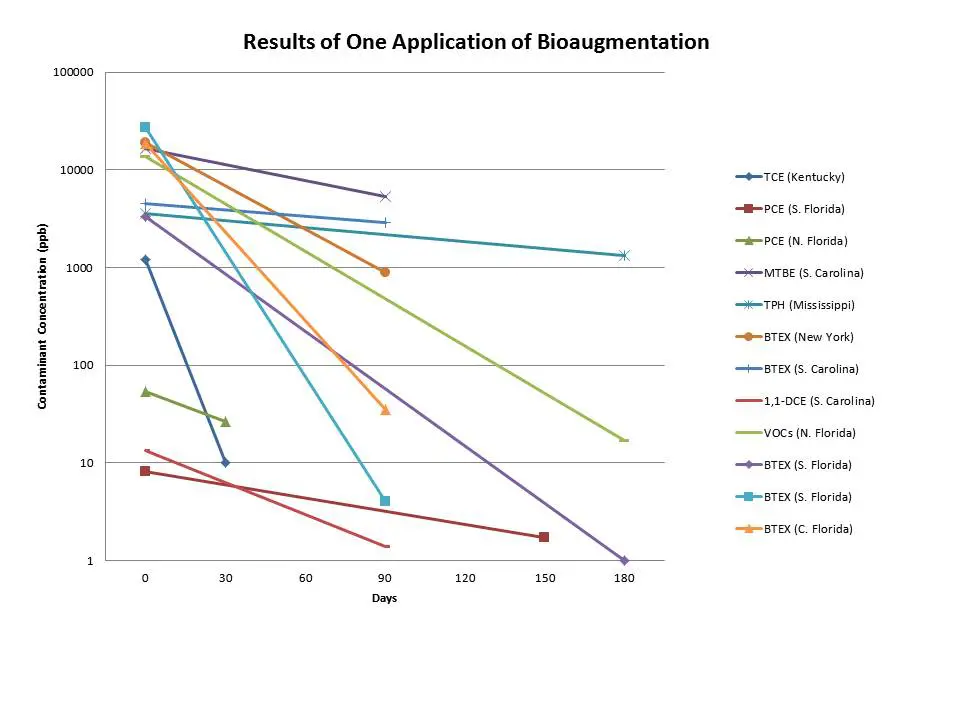

The following applications demonstrate the significant results that can be achieved with a single application of Petrox bioremediation.

Florida Panhandle Gas Station

Facility ID # 32-8520334

Petrox was injected through horizontal drilling to address a ground water plume with limited surface access. After a single Petrox® application there was significant reduction in the contaminant concentrations.

|

Sampling Date |

Benzene |

Toluene |

Ethyl benzene |

Xylene |

Naph-thalene |

2-Methyl naphthalene |

| Pre- bioaugmentation |

11/11/05 |

4,300 |

3,000 |

1,300 |

5,300 |

240 |

48 |

| 10/23/07 |

2,700 |

4,200 |

860 |

5,700 |

240 |

41 |

| Post-bioaugmentation |

11/06/08 |

1.7 |

8.5 |

0.71 |

5.1 |

0.49 |

0.45 |

| 1/22/09 |

0.88 |

0.64 |

0.43 |

1.3 |

0.49 |

0.45 |

All Concentrations shown in µg/L.

Southeast Florida Gas Station

Facility ID 8838788

After removal of USTs, piping and surrounding soils Ground water was treated with 110 gallons of Petrox® by direct injection in June 2009. Sampling six months after the Petrox® treatment showed significant reductions in all contaminants.

|

Sampling Date |

Benzene |

Toluene |

Ethylbenzene |

Total Xylenes |

| Pre- bioaugmentation |

4/4/2008 |

480 |

1800.0 |

110.0 |

900.0 |

| Post- bioaugmentation |

11/12/09 |

<0.5 |

<0.51 |

<0.44 |

<0.5 |

All concentrations shown in µg/L.

Southeastern Florida Marina

Tequesta, Florida

Facility ID # 43-8731703

Subsequent to the removal of petroleum underground storage tanks (USTs), piping and surrounding soils for redevelopment, residual soil and ground water contamination at the site were treated with Petrox® bioremediation. Petrox® was applied to the soil that was removed during the UST removals and to the ground water in the UST cavity.

Approximately 4,000 tons of soil were removed from the excavation and stockpiled on site for treatment. The total BTEX concentrations in the excavated soil were up to 100 mg/kg. Petrox® bioremediation was applied to the stockpiled soils. In less than 90 days the petroleum was no longer detected in the soil and in the soil met the applicable Florida DEP standards.

Petrox® bioremediation was applied to the water in the former UST cavity to treat residual petroleum. The proximity of the cavity to the Jupiter Sound indicated that the ground water was strongly influenced by infiltration from the Sound. After less than 90 days post treatment, the water in the excavation also met the applicable Florida DEP standards.

| Maximum Water Conc. |

Benzene |

Toluene |

Ethylbenzene |

Total Xylenes |

| Pre-treatment |

1,960 |

5,140 |

1,860 |

18,340 |

| 90 days after treatment |

3.7 |

BDL |

BDL |

BDL |

All concentrations shown in µg/L. BDL= below detection limits.

Central Florida Gas Station

Petrox was applied to the ground water in an area around a single monitoring well that did not respond to another treatment as well as the rest of the plume. A single 10-gallon application of Petrox® was sufficient to apply for site closure.

|

Sampling Date |

Benzene |

Toluene |

Ethylbenzene |

Total Xylenes |

| Pre- treatment |

8/2/2007 |

11,100 |

1,250 |

1,260 |

5,040 |

| Post-treatment |

10/4/07 |

1,600 |

20.0 |

290. |

840. |

| 11/19/07 |

0.40 |

1.0 |

1.00 |

32.0 |

All concentrations shown in µg/L.

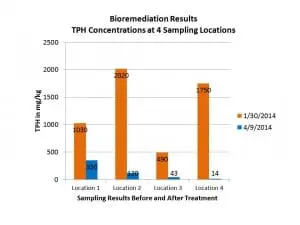

The results show that within 30 days the contaminant concentrations in perched water were reduced by 50%. After 60 days there was slight rebound in come of the contaminants, showing that more soil treatment may be necessary if lower cleanup goals needed to be maintained.

The results show that within 30 days the contaminant concentrations in perched water were reduced by 50%. After 60 days there was slight rebound in come of the contaminants, showing that more soil treatment may be necessary if lower cleanup goals needed to be maintained.