Posts

Soil Bioremediation at Dry Cleaners

/in Chlorinated Solvent Remediation, CL-Out, Dry Cleaners/by Mike SaulPermanently remove vapor intrusion risk

Soil bioremediation is a more effective strategy for managing the vapor intrusion risk at dry cleaners where solvents have contaminated soil or shallow ground water. Soil bioremediation quickly eliminates the problem, while long-term vapor mitigation ties up resources in on-going operation, maintenance and monitoring costs. Soil bioremediation eliminates the source of vapors entering the cleaners and adjoining properties. The source removal restores the full property value without disrupting operations.

CL-Out microbes have been used at many sites in the US and Canada to remove PCE contamination from soil at dry cleaners and other industries where solvents are used. CL-Out is a consortium of microbes selected for their ability to cometabolize chlorinated solvents under aerobic conditions. The microbes are pumped into the soil through small boreholes in the building or surrounding area. Once in the soil, the microbes produce metabolic enzymes that convert the PCE into carbon dioxide and water without generating harmful by products.

The following case studies are examples of how quickly and cost effectively CL-Out bioremediation removes the soil contamination:

Chicago, Illinois

CL-Out bioremediation reduced concentrations of dry cleaning solvents in soil to allow for the redevelopment of a property into luxury condos. After the old building was removed, the contractor mixed CL-Out microbes into the PCE-contaminated soil. After 90 days the soil was tested to verify success.

The 90-day sampling showed that the remediation met the site cleanup standards. PCE was reduced by more than 95% from a maximum of 3,100 mg/kg to less than 120 mg/kg. A “No Further Action” letter was submitted to IEPA. The CL-Out cost for the project was $13,000.

Orange County, California

At a site in southern California, the soil and ground water contamination was removed at at operating dry cleaners without interrupting the business operations. CL-Out microbes were injected into the soil and ground water through small-diameter borings. Inside the building, hand-dug borings less than 3-inches in diameter were used for the treat the soil. Two drums of CL-Out microbial solution were injected into 80 cubic yards of contaminated soil.

After 30 days soil sampling showed the PCE concentration was reduced by 85% from 775 ug/Kg to 115 ug/Kg. No daughter product were generated during the bioremediation.

The ground water was treated simultaneously and the contaminant concentrations were reduced by more than 90%.

The cost for CL-Out to treat both soil and ground water was $9,500.

Click here to view the full case study.

Call CL Solutions to discuss removing the vapor intrusion risk at your property.

Petrox Bioremediation Prepares Urban Bulk Fuel Facility For Reuse

/in Chemical Industries, Petrox/by Mike SaulSoil Recycling Prepares Site for Redevelopment

A 30 acre bulk fuel facility is ready for reuse after on-site bioremediation of nearly 100,000 tons of petroleum-contaminated soil in an urban setting near Los Angeles. Bulldog Green Remediation of Walnut Creek, California used a proprietary ex situ treatment process combining Petrox organisms in a custom blend to remediate the soils. All soil was treated and reused on site. This closed-loop process eliminated 8,000 truck loads of soil from the roads and landfills in southern California.

The treatment process reduced contaminant concentrations from typical levels of 1,000 to 10,000 mg/kg to less than 100 mg/kg in less than 30 days. This rapid treatment rate made possible continuous cycling from excavation, through treatment, and back filling.

The site is now ready for reuse as a park and other development.

Land Farming Application Reduces TPH by 90% to 99%

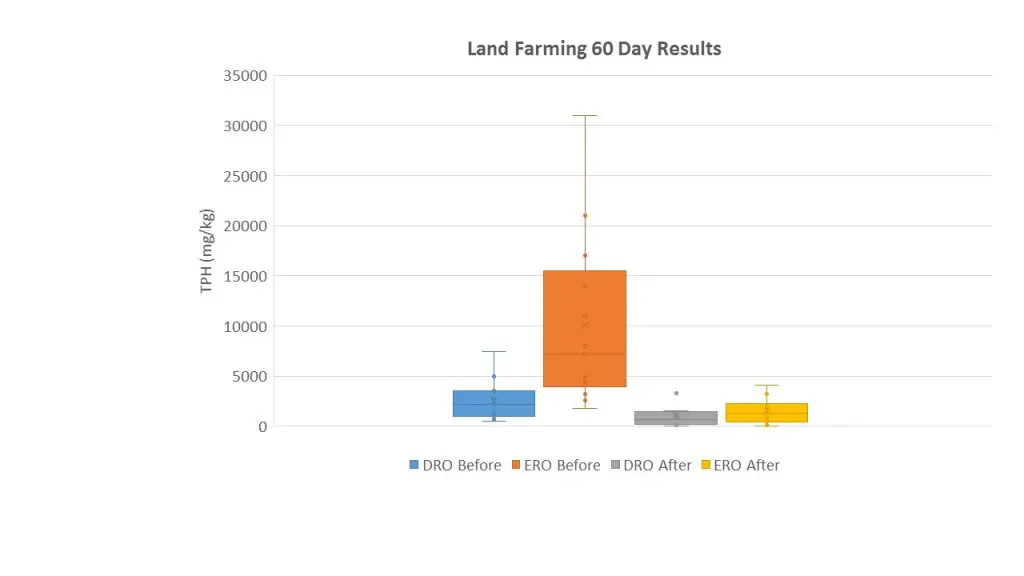

/in Excavated and Land Farmed Soils, Gas Stations, Industrial Sites, News, Oil Fields, Oil Spill Remediation, Petroleum Remediation, Petrox, Sustainability/by Mike SaulPetrox microbes were added to excavated petroleum-contaminated soil to accelerate the degradation of DRO and ERO total petroleum hydrocarbons. Petrox was added by spraying the surface of the soil with a hydrated Petrox solution. The microbes were mixed into the soil using a tractor-mounted disc tiller.

After approximately 60 days, soil samples were taken for testing. The soils showed 90% to 99% petroleum removal. The following chart shows the range of DRO and ERO concentrations before and after Petrox treatment.

Soil Mixing to Improve Distribution of Microbial Solution

/in Chemical Industries, Chlorinated Solvent Remediation, Gas Stations, Industrial Sites, News, Oil Fields, Oil Spill Remediation, Petroleum Remediation, Petrox, Sustainability/by Mike SaulBioaugmentation results can be accelerated and amplified by soil mixing to improve distribution and contact. The equipment shown in this example was used to blend Petrox with contaminated soil to a depth of 10 feet.

Contact Us

CL Solutions

1775 Mentor Ave., Suite 705

Norwood, OH 45212

Call: 513-284-5940