Posts

Fast Creosote Bioremediation Results

/in Custom Blend microbes, Industrial Sites, Petroleum Remediation/by Mike SaulBioremediation of Waste Treated Wood

Fast creosote bioremediation was recently demonstrated by a user of a custom blend of CL Solutions organisms. The environmental consulting firm applied the microbes to finely shredded wood that had been saturated with creosote. The initial testing results after bioaugmentation showed a reduction of the creosote concentration by 57% in just 7 days. The concentration measured as total recoverable hydrocarbons decreased from 3,453 mg/kg to 1,497 mg/kg.

Improving Long-Term Bioremediation Results with Nutrients

/in Gas Stations, Industrial Sites, Oil Fields, Oil Spill Remediation, Petroleum Remediation, Petrox, Sustainability/by Mike SaulAdding Nutrients Increases Long-Term Population and Bioremediation Results

The goal of bioaugmentation is to improve the rate of contaminant removal by adding a high population of beneficial microbes to the contaminated media. The additional microbes should provide short-term benefit as the microbes begin metabolizing the contaminants immediately upon injection. But what benefit does bioaugmentation provide in the long term? And how much benefit does bioaugmentation provide over biostimulation by adding nutrients to the native organisms?

A client of CL Solutions completed a bench-scale study to answer these questions. A bench-scale study was preferred to a field study because it removes the potential distribution and time-lag issues associated with the distances between injection and monitoring locations in the field.

Samples of petroleum-contaminated soils were obtained and separated into split samples for treatment with microbes and nutrients. Some were untreated for comparison. Samples were tested for petroleum concentrations, including C-fraction concentrations after 30, 40 and 60 days. Heterotrophic populations were measured at 40 and 60 days.

The tests showed the following results in the early stages:

- All of the treated samples showed more than 80% total petroleum reduction in the first 30 days.

- The sample treated with nutrients only had the same level of petroleum removal as the bioaugmented samples in the first 30 days.

- The heterotrophic population of the biostimulated sample was as high as in the bioaugmented samples at 40 days.

After 30 days the situation changed.

- The bioaugmented microbial population continued to increase after 40 days and may have increased by a factor of 100 times. Meanwhile, the biostimulated population appeared to stall.

- The petroleum removal continued in the bioaugmented samples and reached as high as 93% removal. In comparison the biostimulated sample stalled at 82% removal.

- The difference appears to be that the bioaugmented samples removed the C-21 to C-35 concentrations at a much higher rate than the biostimulated sample.

- Phenanthrene was target chemical for bioremediation. The biostimulated sample showed 39% removal while the bioaugmented samples showed complete removal to BDL.

Overall, the superior performance of the bioaugmented samples appears to be related to having a greater metabolic range that removed the heavier hydrocarbon fractions. Microbes with the extended metabolic range could continue to multiply as they grew on the heavy hydrocarbon fraction. The results are consistent with field results showing the recalcitrance of heavier hydrocarbon fractions and compounds like naphthalene and phenanthrene under natural attenuation.

Contact CL Solutions for more information and insights.

Petrox Bioremediation Prepares Urban Bulk Fuel Facility For Reuse

/in Chemical Industries, Petrox/by Mike SaulSoil Recycling Prepares Site for Redevelopment

A 30 acre bulk fuel facility is ready for reuse after on-site bioremediation of nearly 100,000 tons of petroleum-contaminated soil in an urban setting near Los Angeles. Bulldog Green Remediation of Walnut Creek, California used a proprietary ex situ treatment process combining Petrox organisms in a custom blend to remediate the soils. All soil was treated and reused on site. This closed-loop process eliminated 8,000 truck loads of soil from the roads and landfills in southern California.

The treatment process reduced contaminant concentrations from typical levels of 1,000 to 10,000 mg/kg to less than 100 mg/kg in less than 30 days. This rapid treatment rate made possible continuous cycling from excavation, through treatment, and back filling.

The site is now ready for reuse as a park and other development.

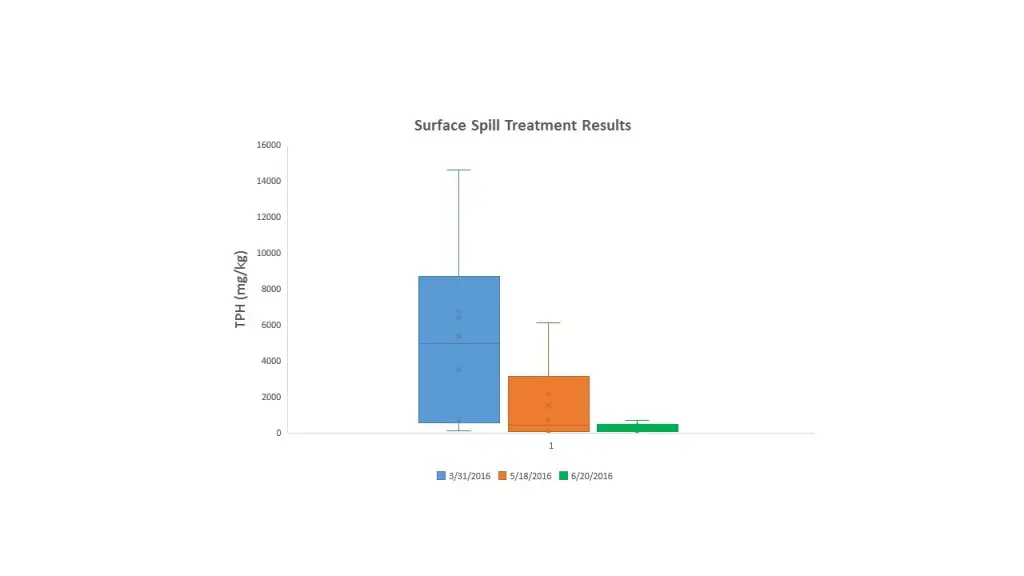

Surface Oil Spill Bioremediation

/in Auto Dealerships, Chemical Industries, Gas Stations, Industrial Maintenance, Petrox/by Mike SaulPetrox microbes provide quick response surface oil spill bioremediation. Petrox can be applied to the oil surface with a backpack sprayer to initiate rapid bioremediation. This approach protects surface water and vegetation with minimal surface traffic.

In the following example, an oil spill affected the vegetation and surface water at the edge of a lake. Contractors applied Petrox to the oil surface on vegetation and soil. Periodic soil samples tracked the results. After 90 days, the maximum and average concentrations decreased by more than 95% at a very low cost.

Contact Us

CL Solutions

1775 Mentor Ave., Suite 705

Norwood, OH 45212

Call: 513-284-5940